Tooling and Die Engineering

Next level Tooling and Die Engineering.

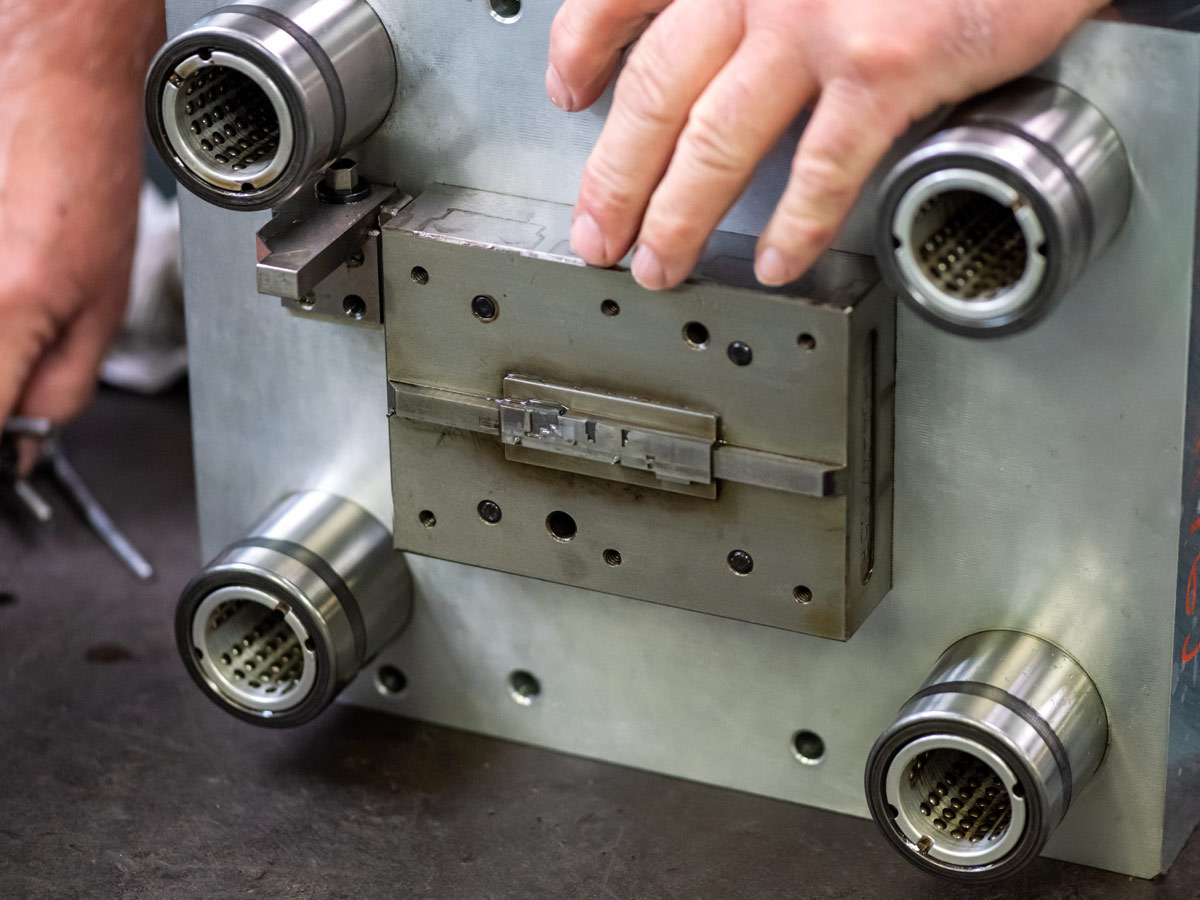

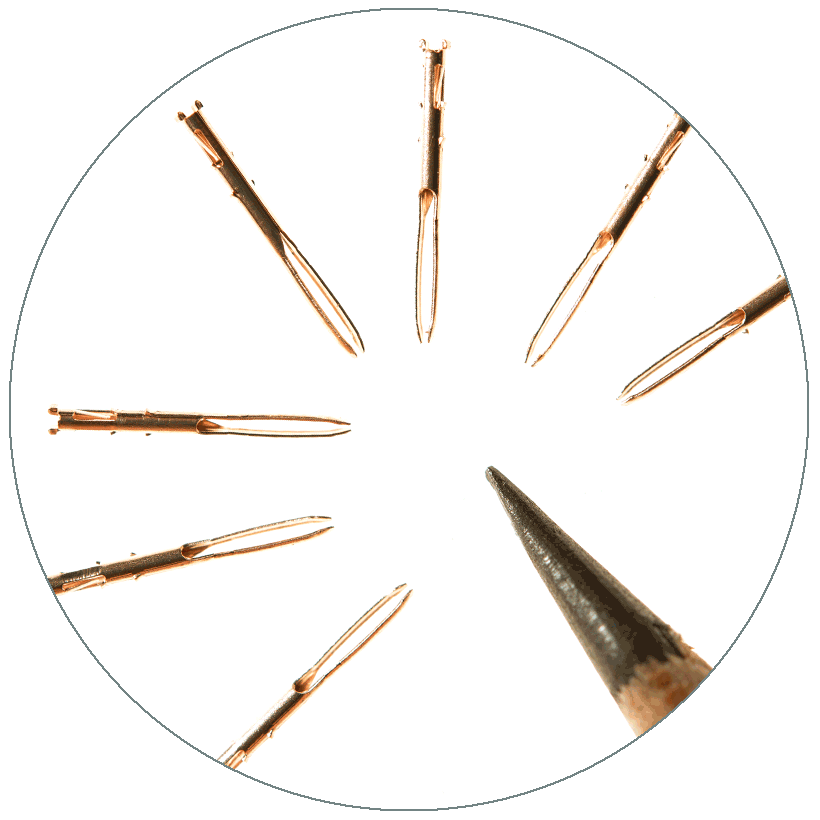

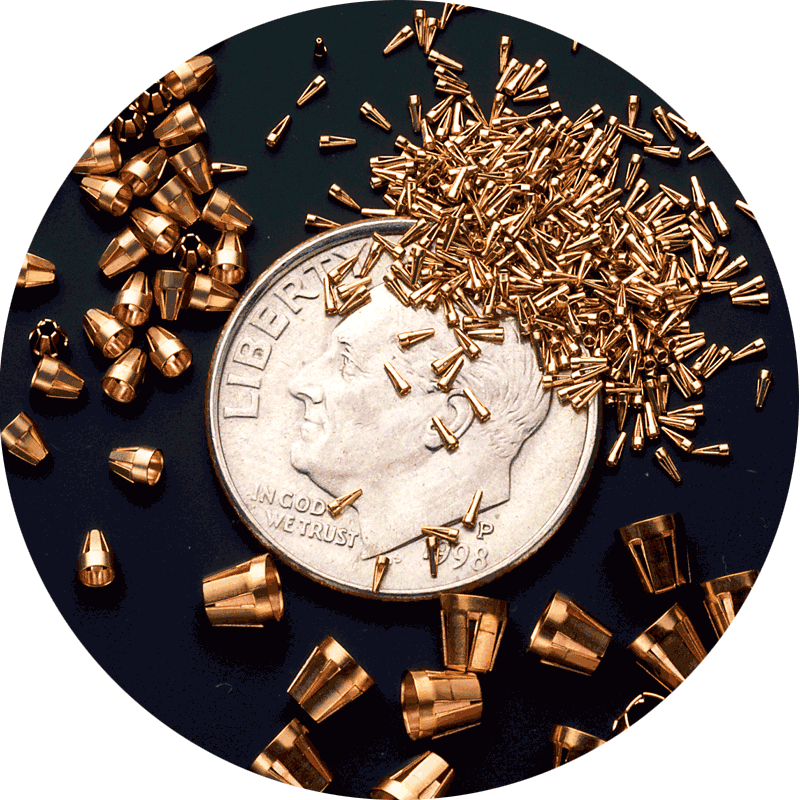

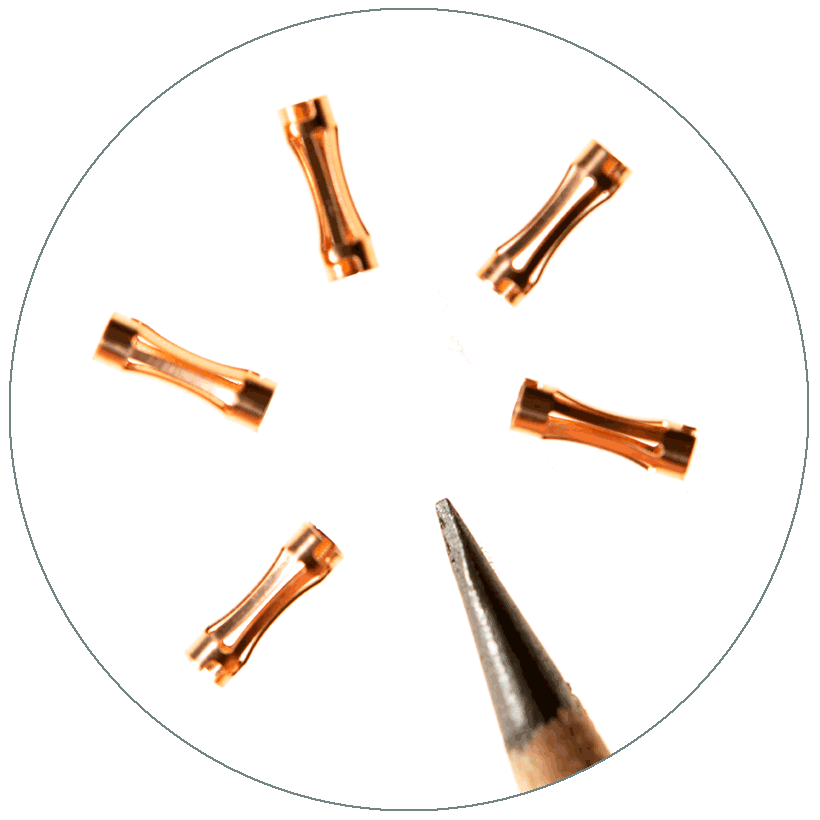

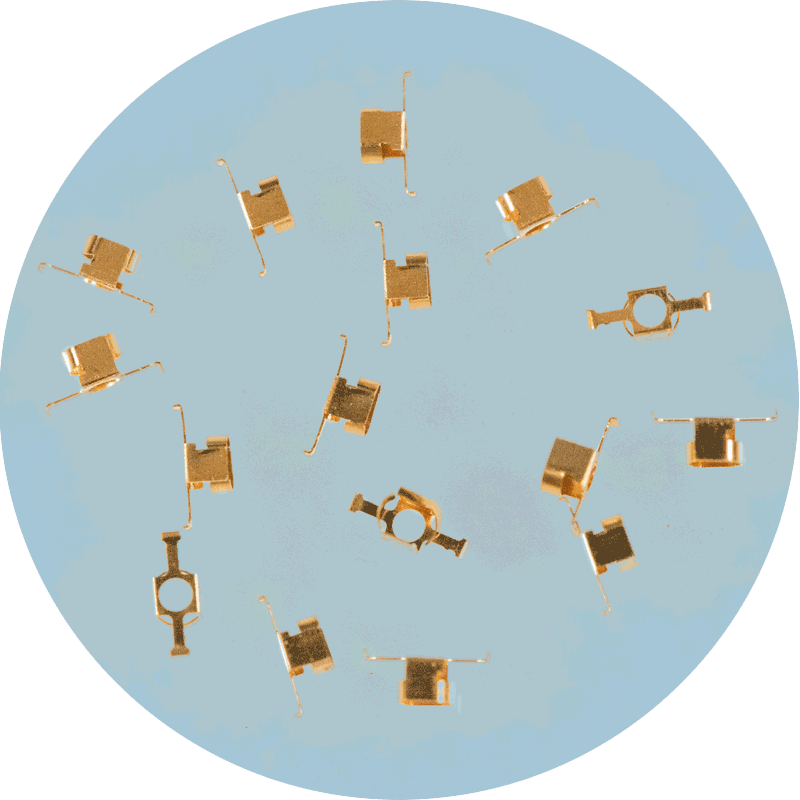

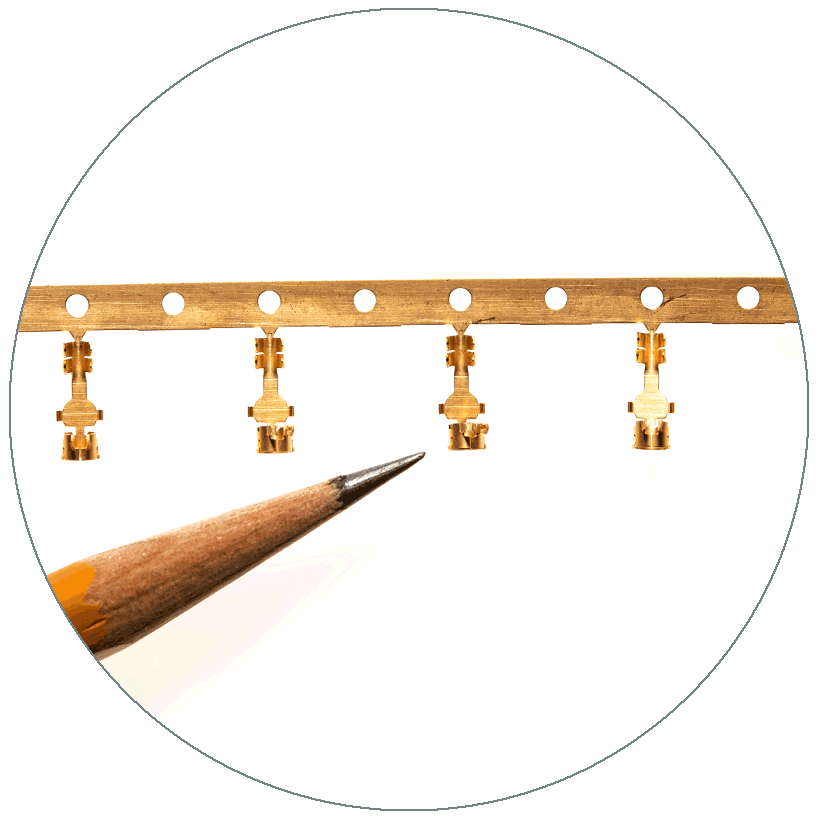

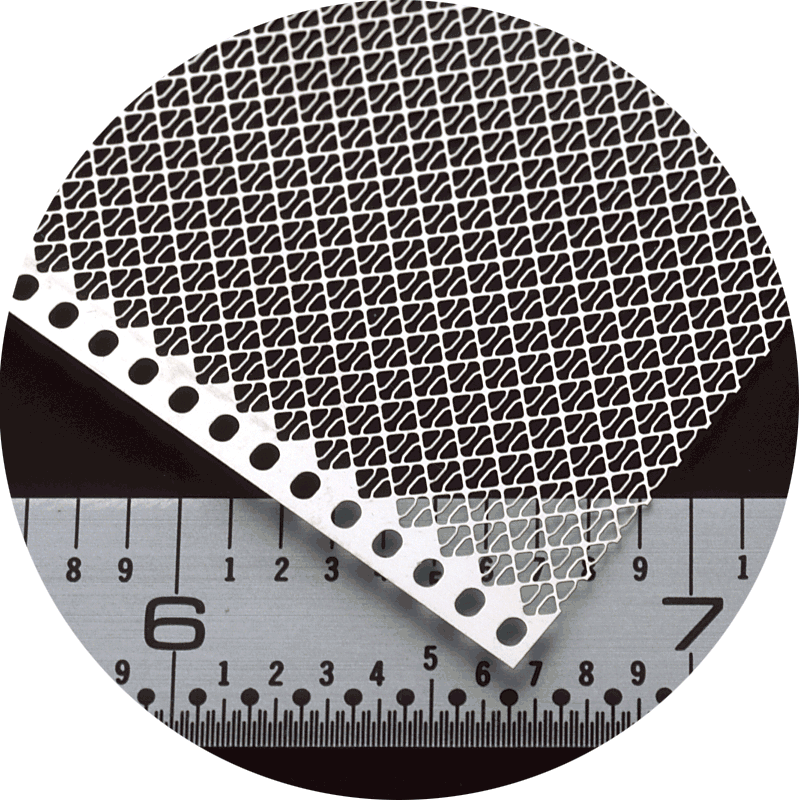

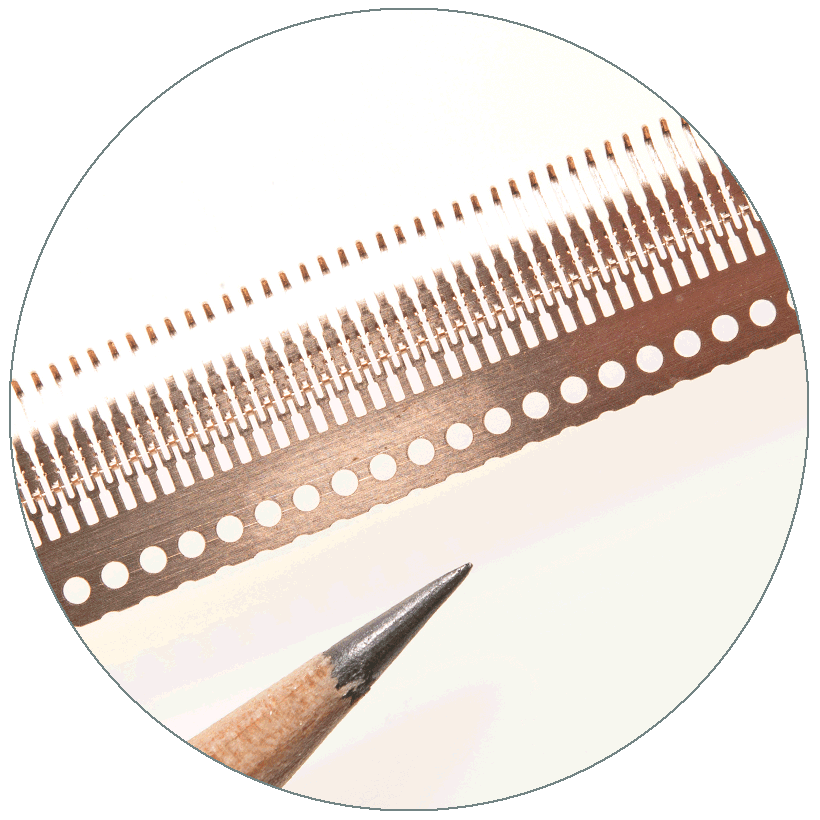

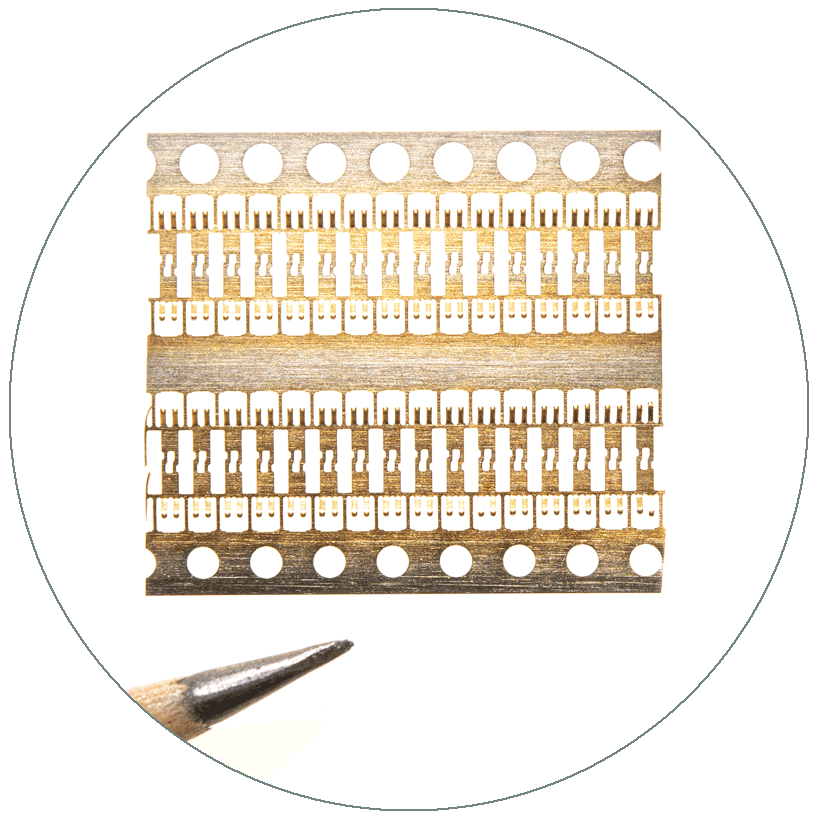

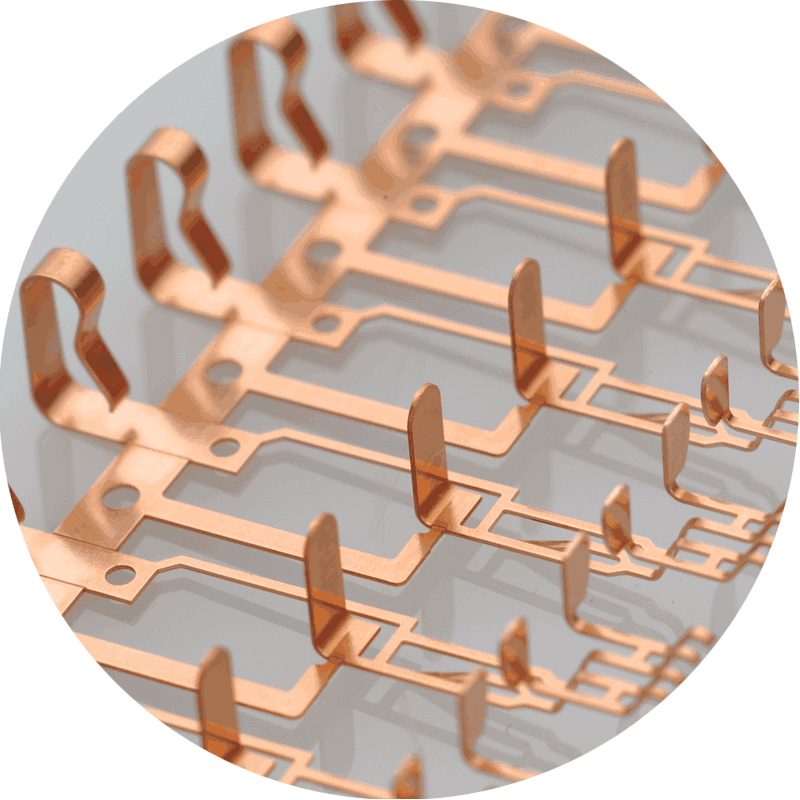

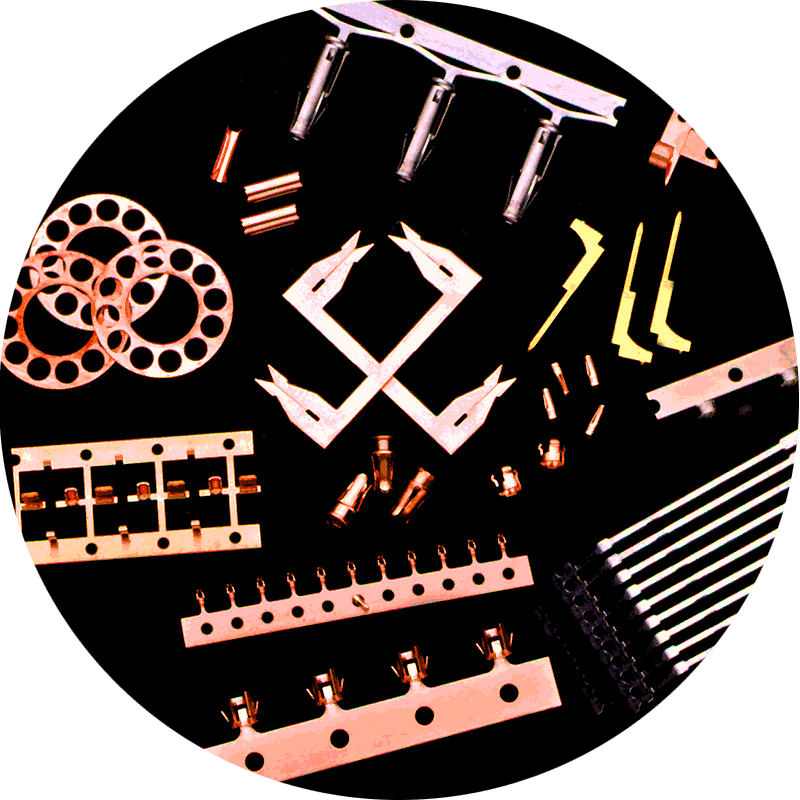

Ditron Tooling and Die Engineering brings proven engineering practices to the next level. Our approach to die engineering is fueled by innovative thinking, but grounded by decades of Stamping experience. Vast manufacturing knowledge, combined with early engineering involvement, enables us to thoroughly understand your critical needs and incorporate them into the tool design and construction. With tolerances specified, function detailed, and program needs understood, we then set out to design tooling using cutting edge 3-D CAD technology.

Focused on Stamping performance — and part integrity.

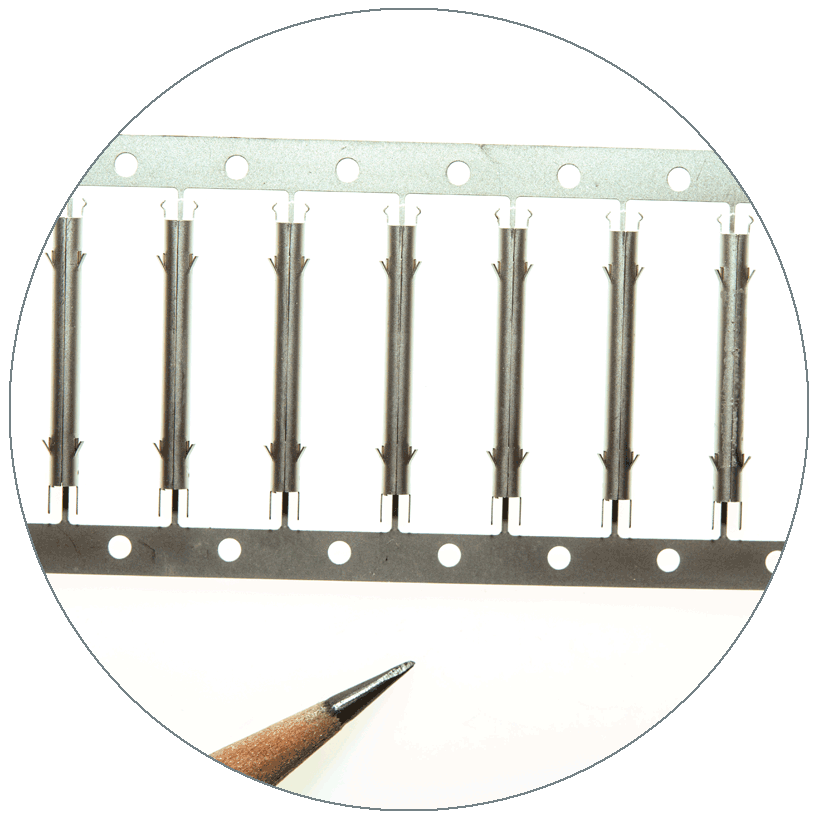

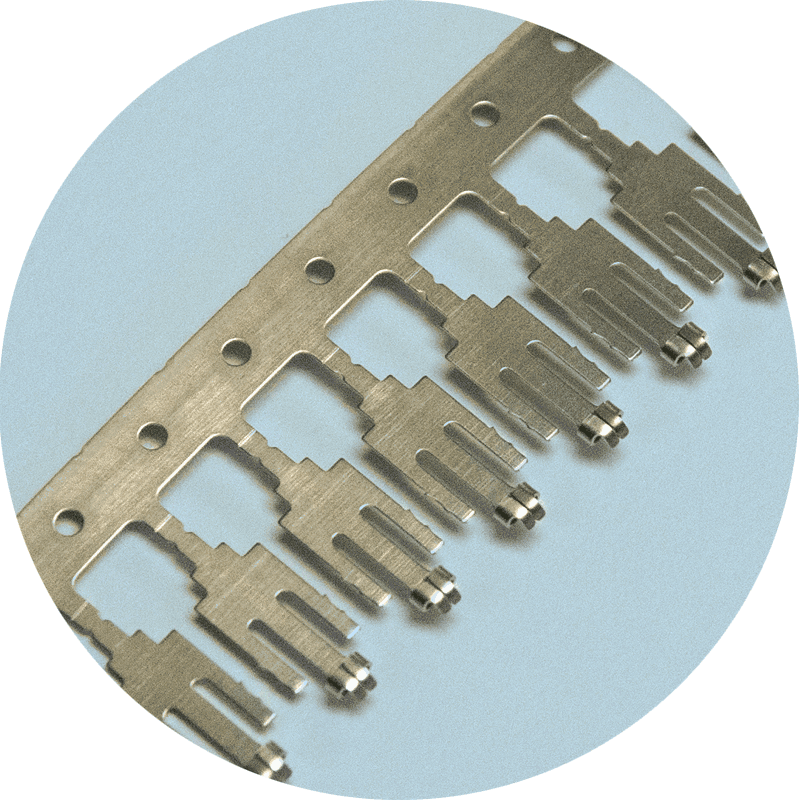

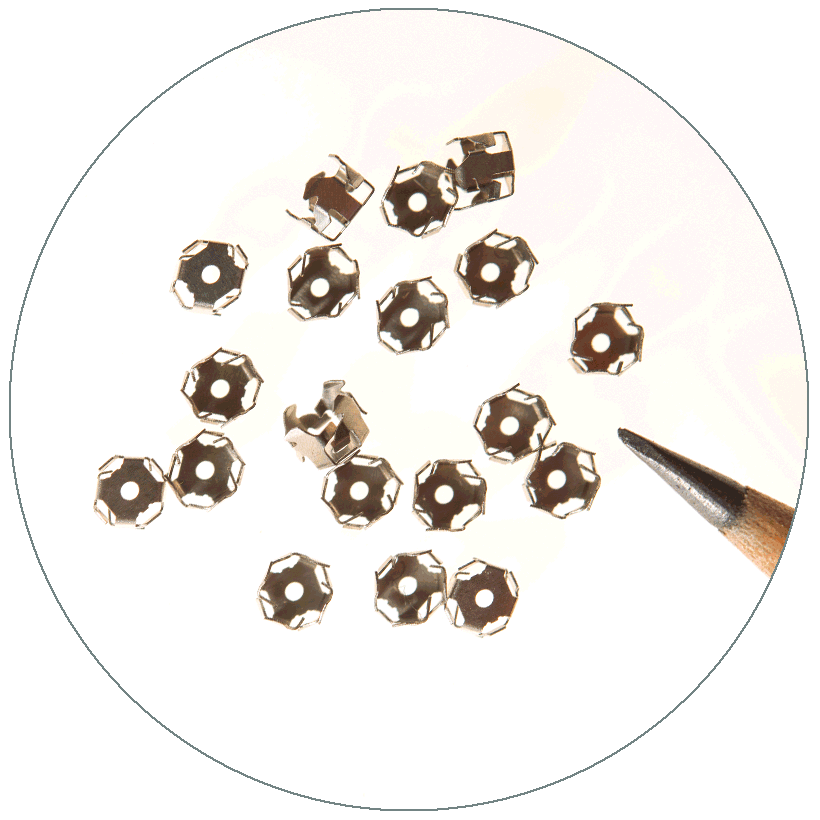

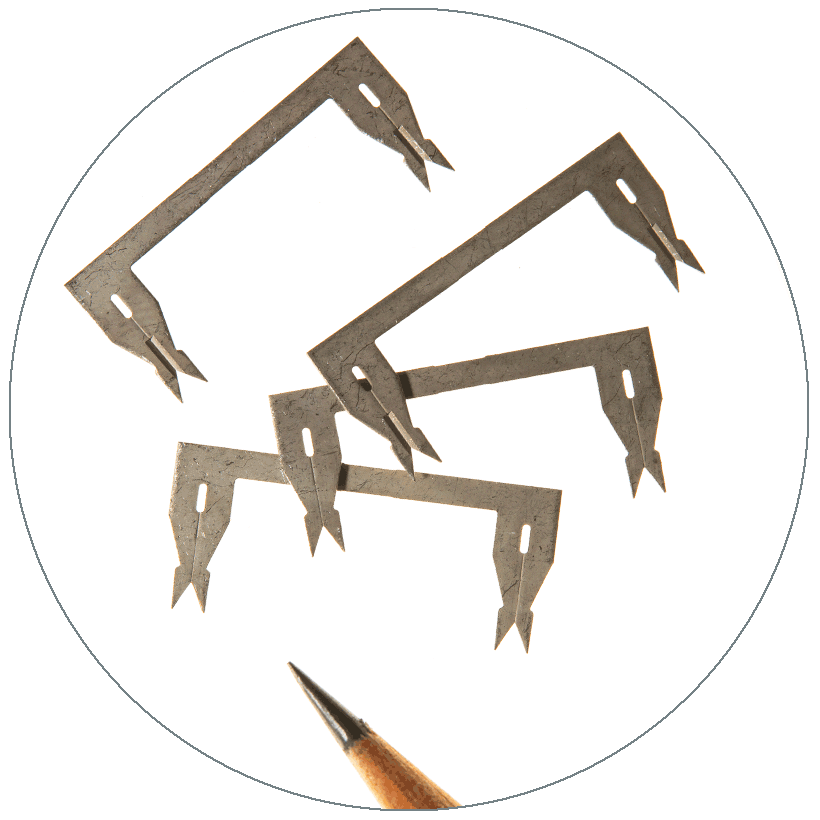

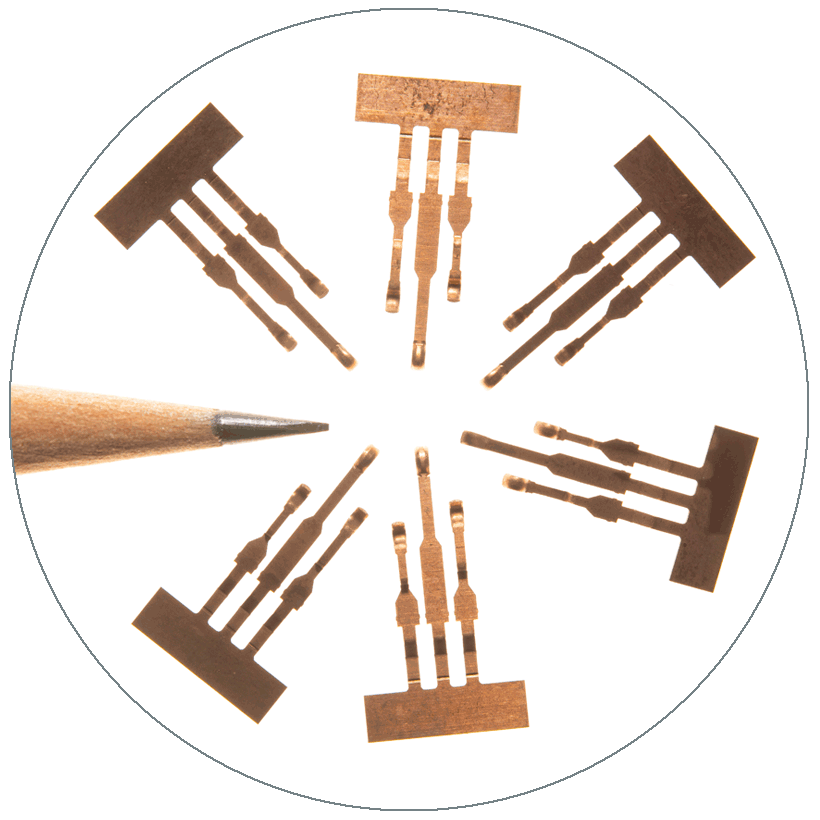

Our Tooling Engineers strive for high speed and volume stamping performance while considering critical product features, stamping behaviors, and discoveries revealed through prototyping and testing. We are constantly seeking paths to improvement—but also always on the lookout for characteristics that could be problematic to production run integrity.

As a result, we generate extremely robust, progressive dies capable of producing components with limited variability to meet or exceed a Six Sigma quality level on critical part features. All at amazing press speeds — with efficiency, extended press-cycle durability, and minimized maintenance. As part of our customer-first service, customers receive Gantt Charts to monitor Tooling progression and advancements.

QUALITY CONTROL >>

Ditron Engineering support includes:

ENGINEERING LOGISTICS

PART DESIGN

PROTOTYPING DESIGN