Tooling, Die Building, and Refinement

Ditron Engineers are Tooling and Die Building experts.

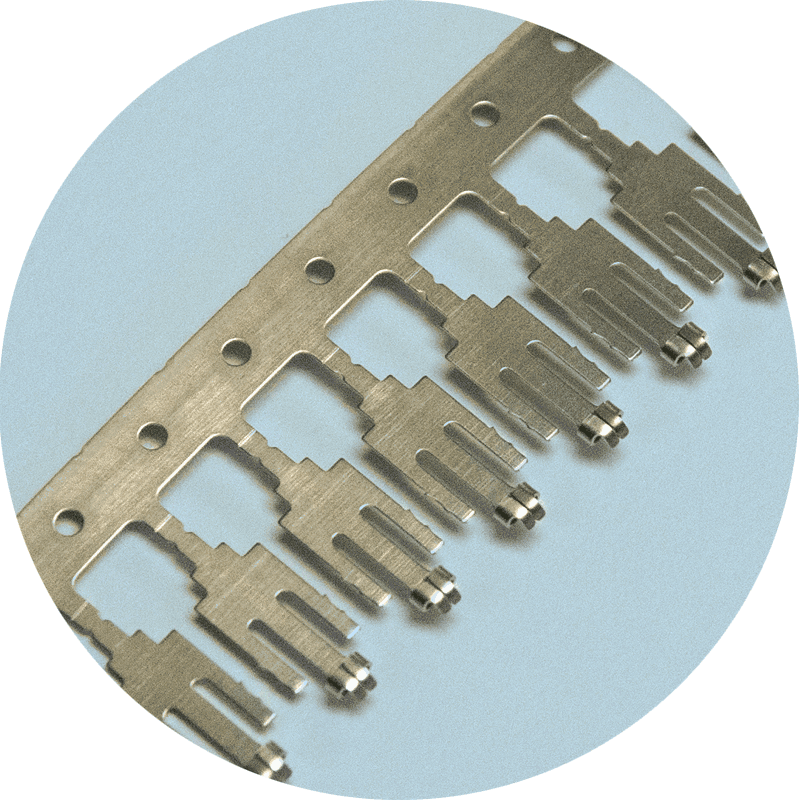

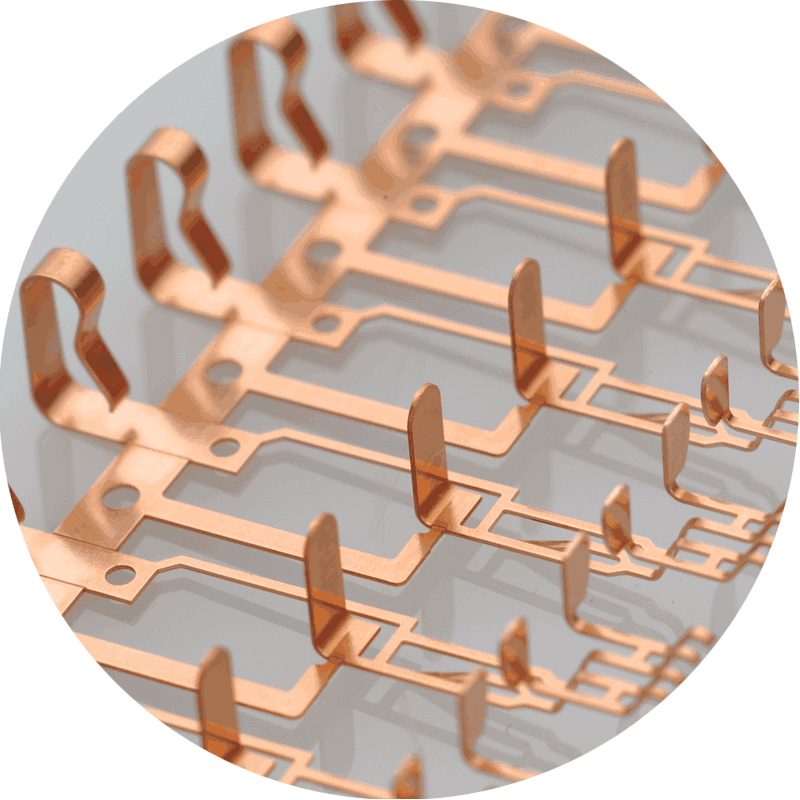

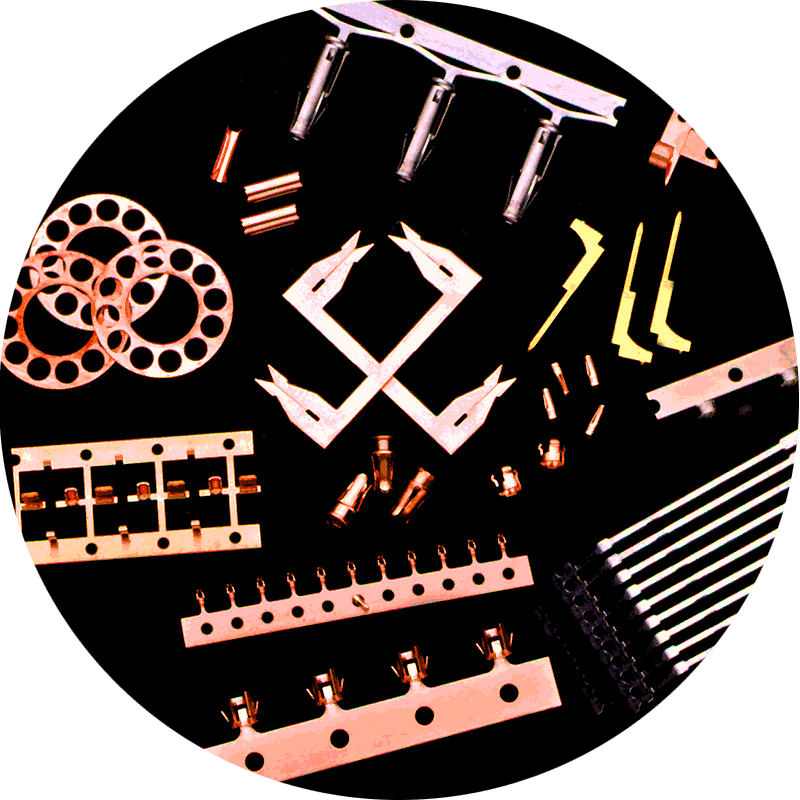

When it comes to Tooling and Die Building, Ditron Engineers consider Tool Design options, Die configurations, and predicted stamping efficiencies during the earliest stages of development. This early involvement, combined with our manufacturing knowledge, allows us to thoroughly accomodate your critical part needs through production-efficient Tool Design and construction.

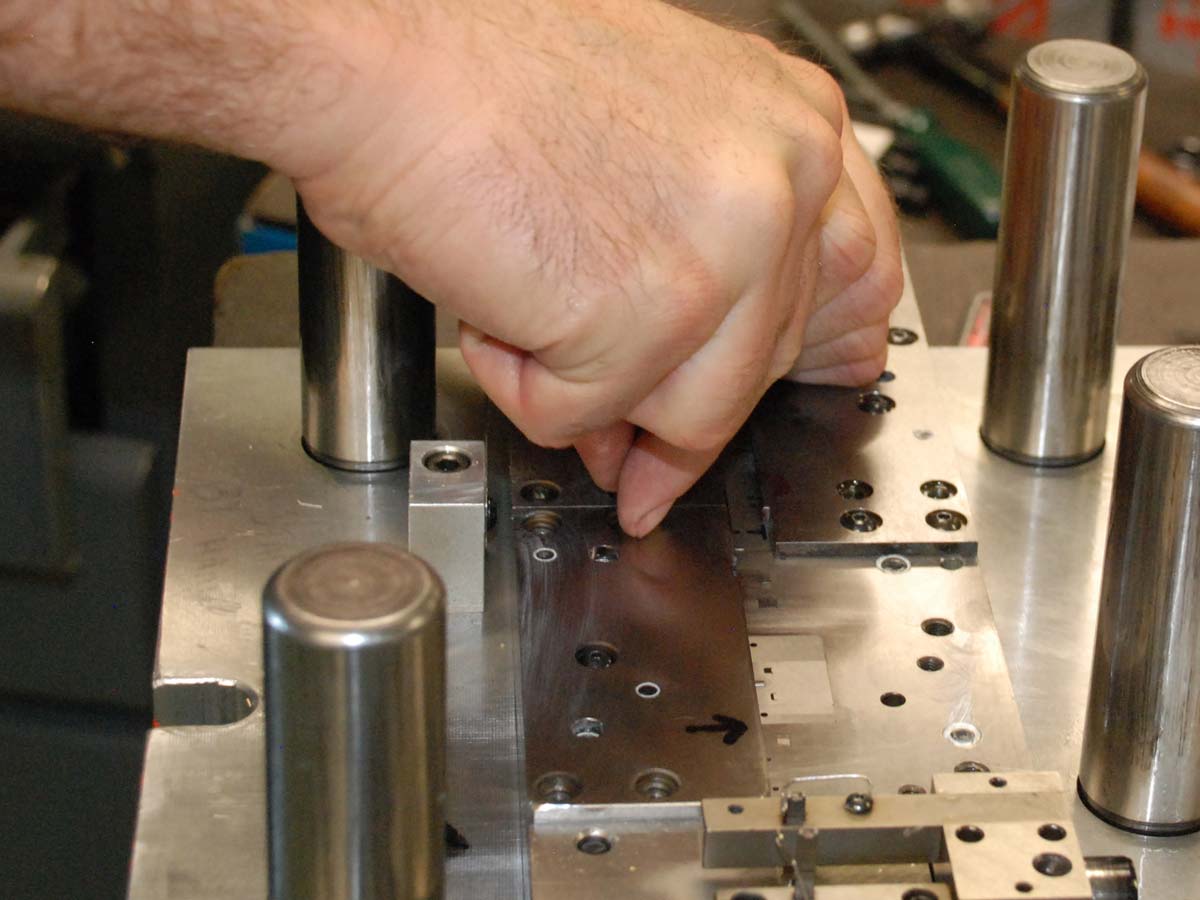

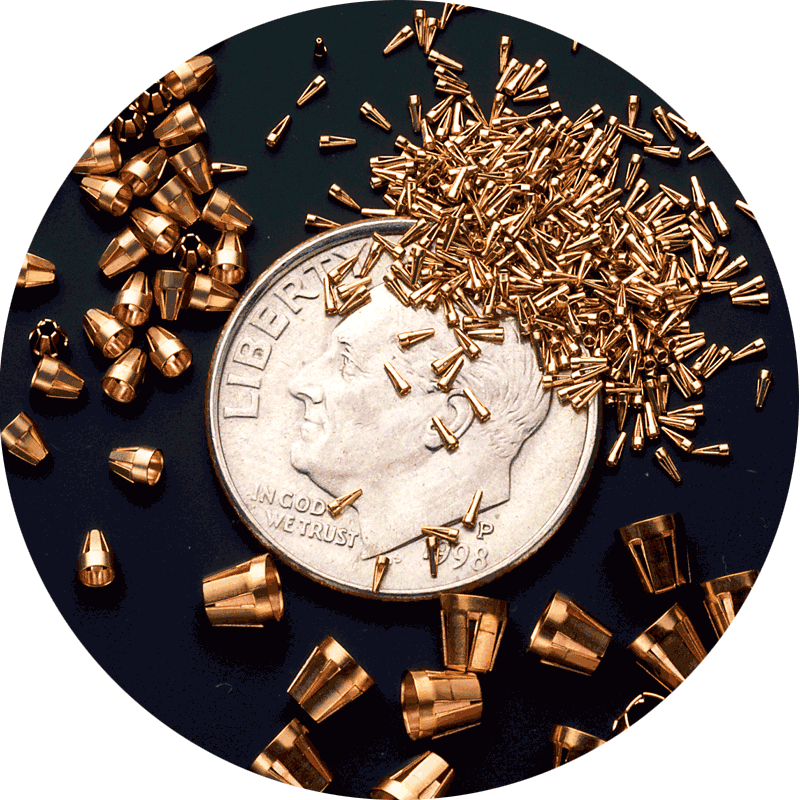

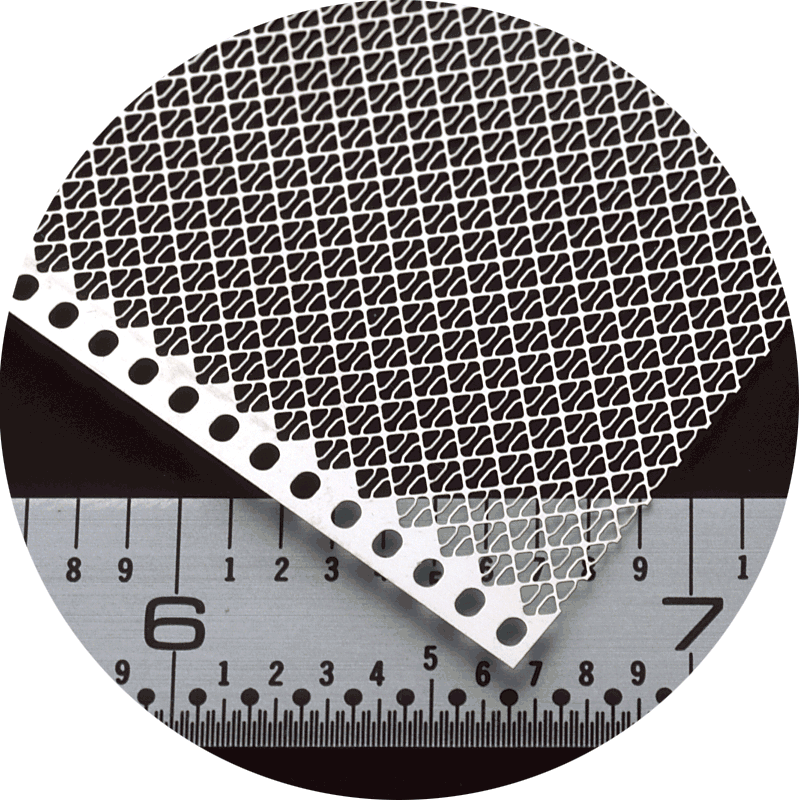

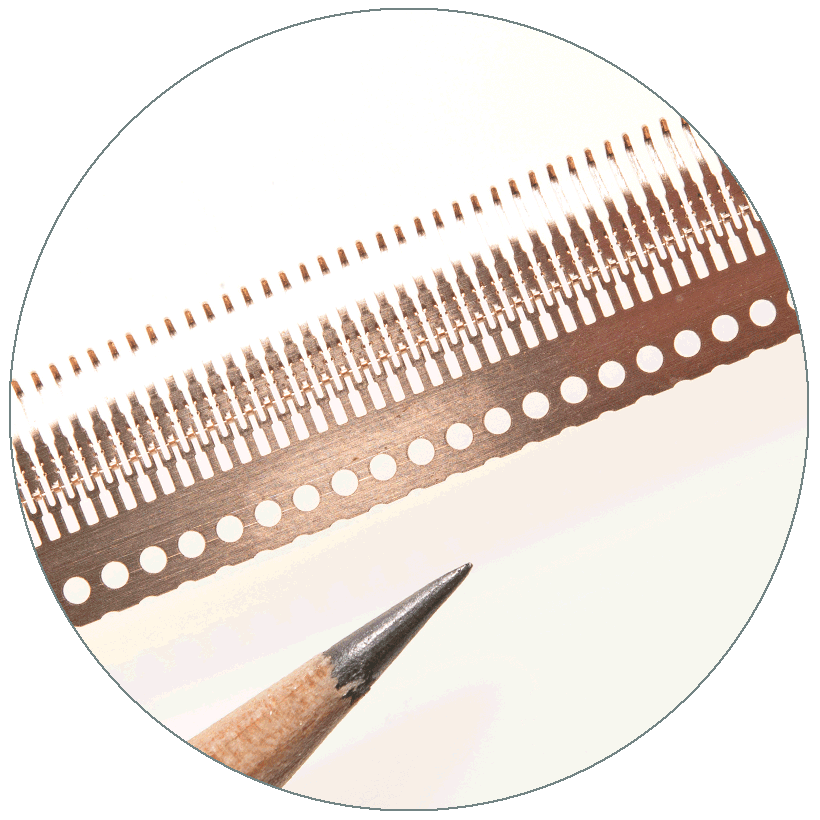

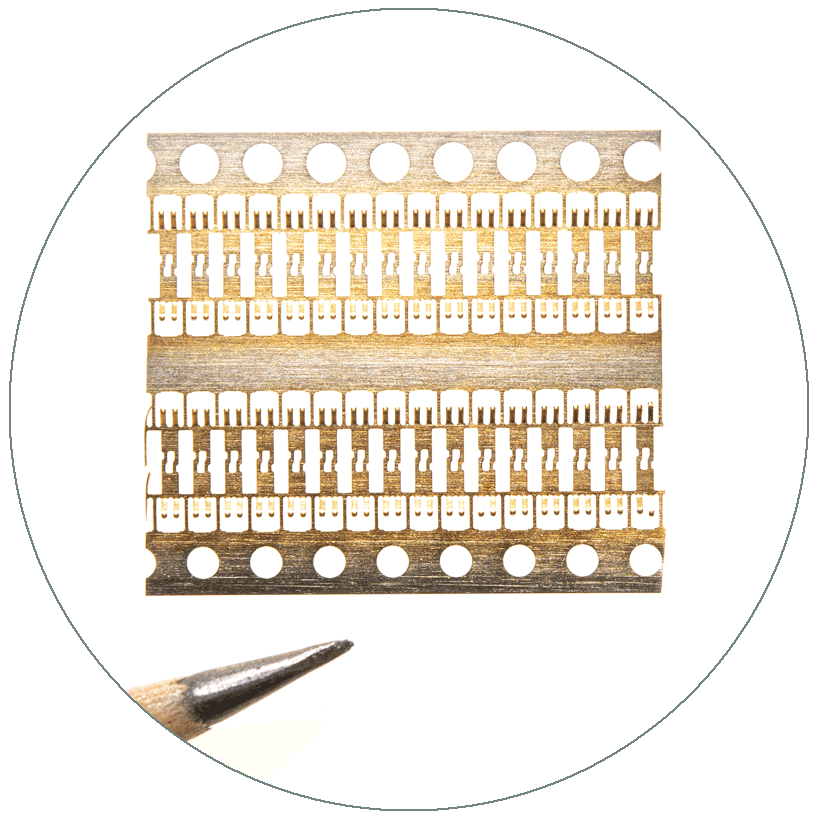

Staffed by Tooling Engineers and highly trained Master Diemakers, our extensive Tooling Department follows a protocol that accommodates numerous early revisions as we hone-in on optimum Die configuration. The result? An extremely robust progressive die capable of producing components with limited variability to meet or exceed a Six Sigma quality level on critical part features.

To keep customers updated on their new tooling programs, Ditron’s Engineering Department issues weekly Gantt Charts tracking all steps of the Tooling effort.

Knowledge-based Tooling solutions.

Our state-of-the-art Tool Room is designed to promote a smooth flow of the building processes. Using “Knowledge Based Machining,” our tool building efforts are supported by CIM (Computer Integrated Manufacturing) software that is fully integrated with our CAD system and Engineering Department. Once the CIM process has been debugged and proven, it is downloaded to our EDM center where fabrication begins.

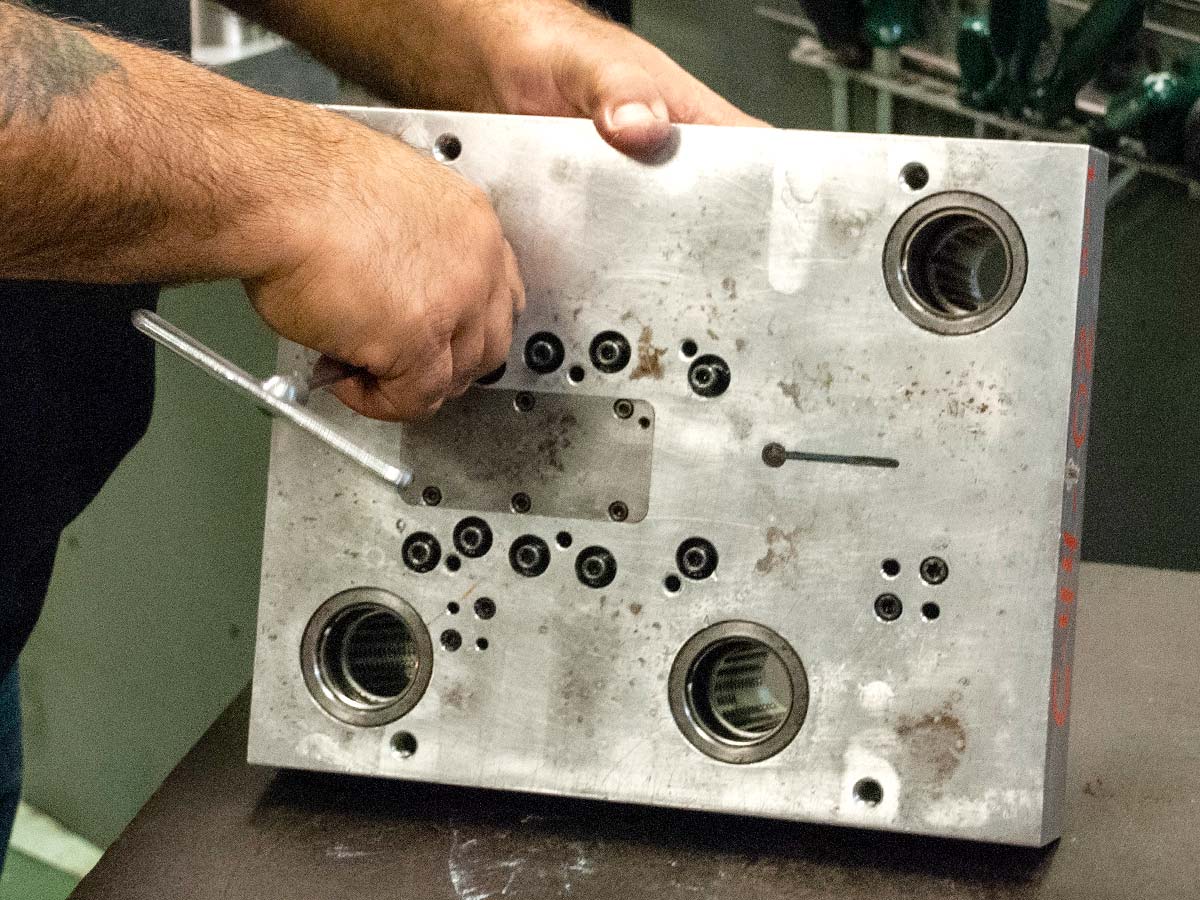

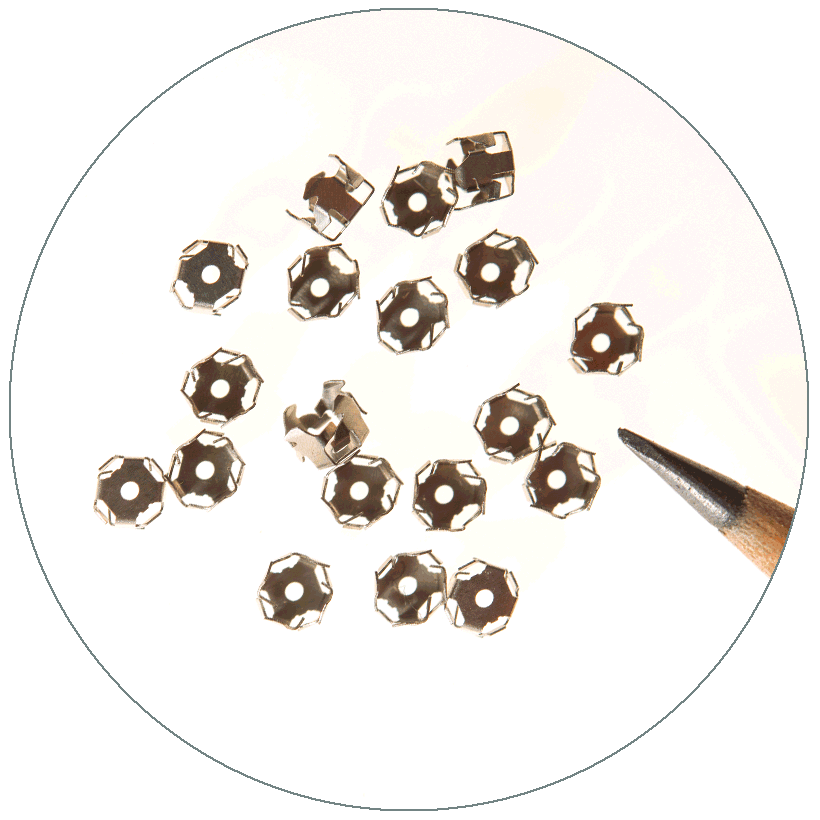

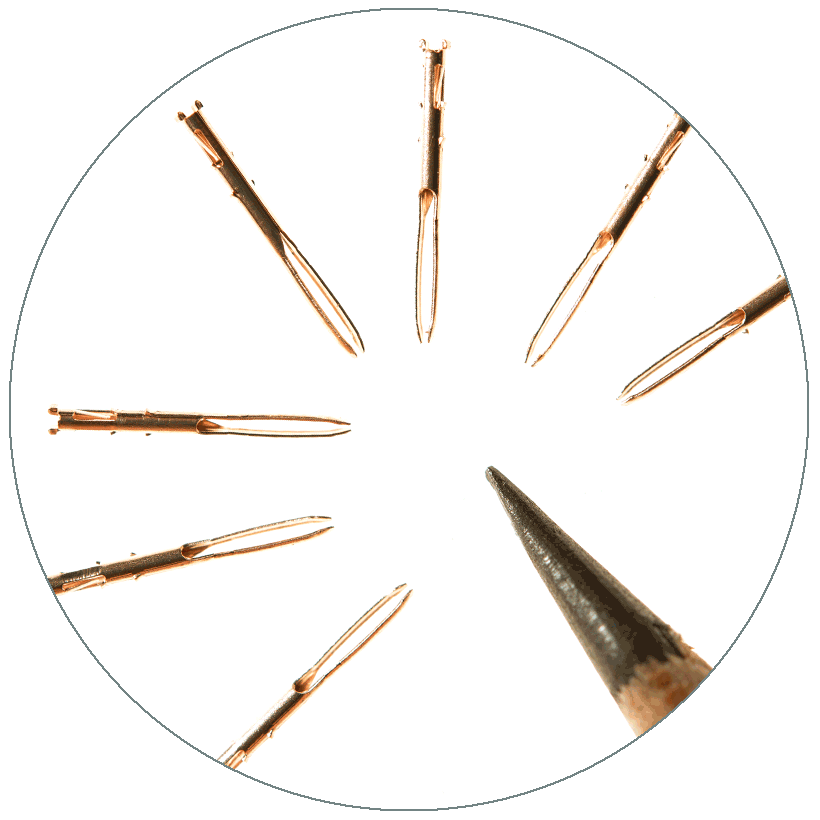

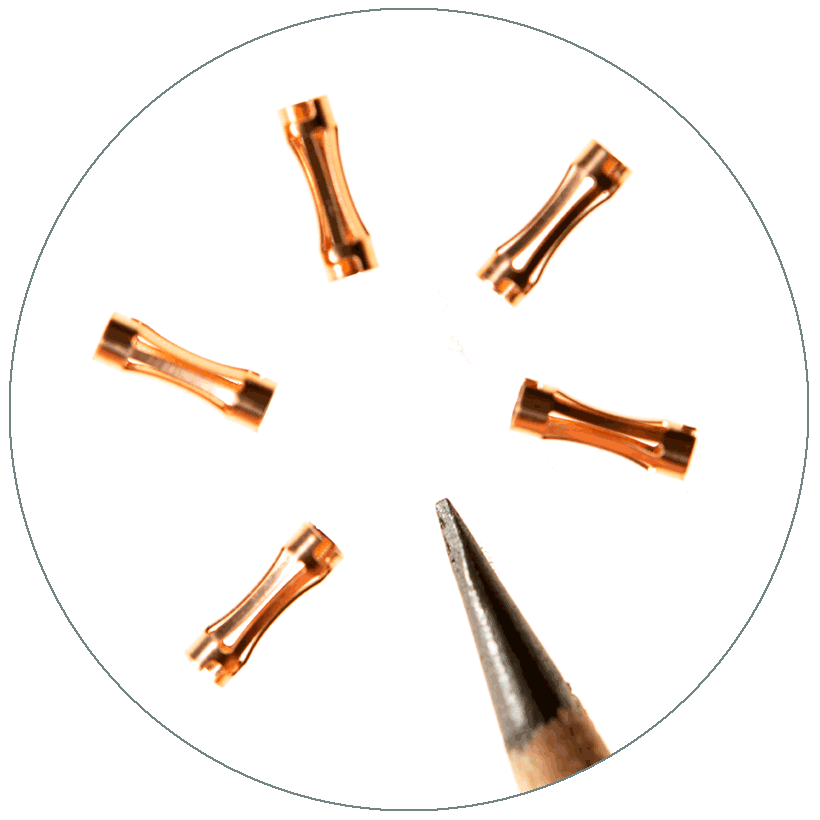

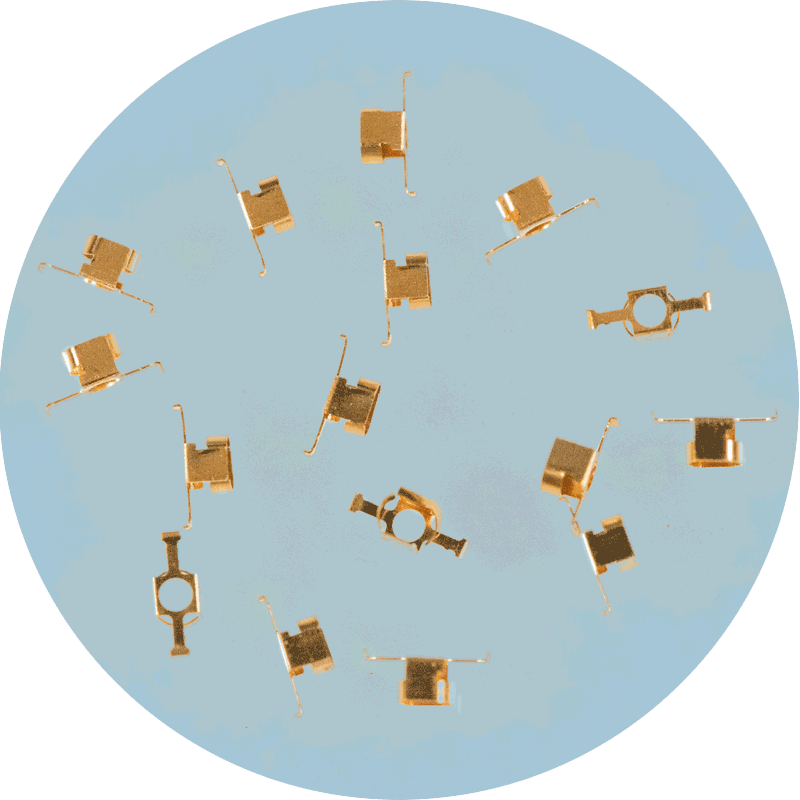

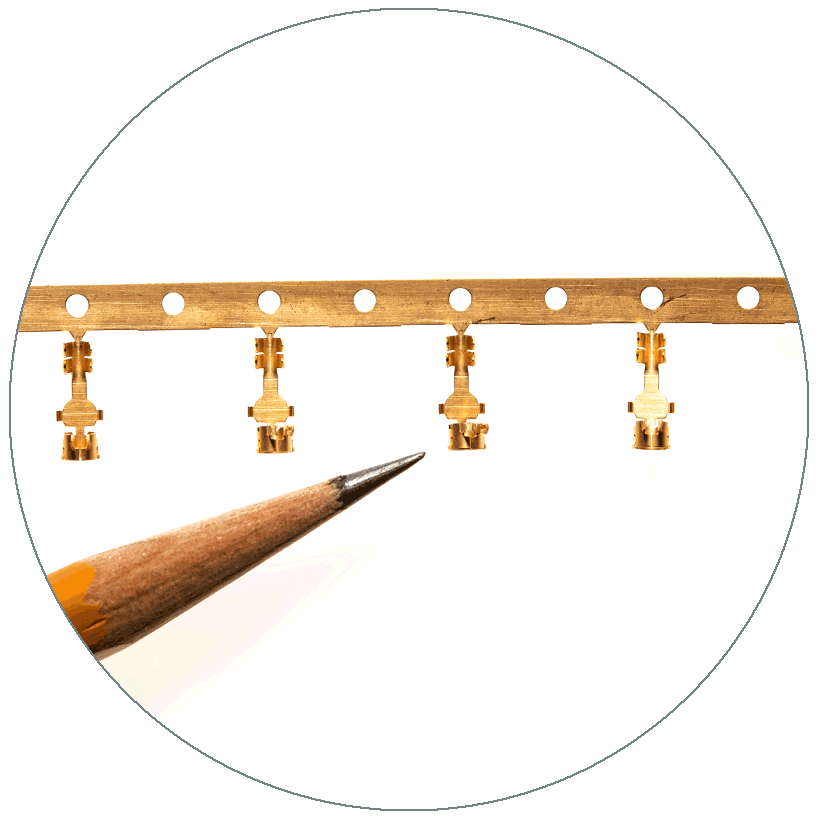

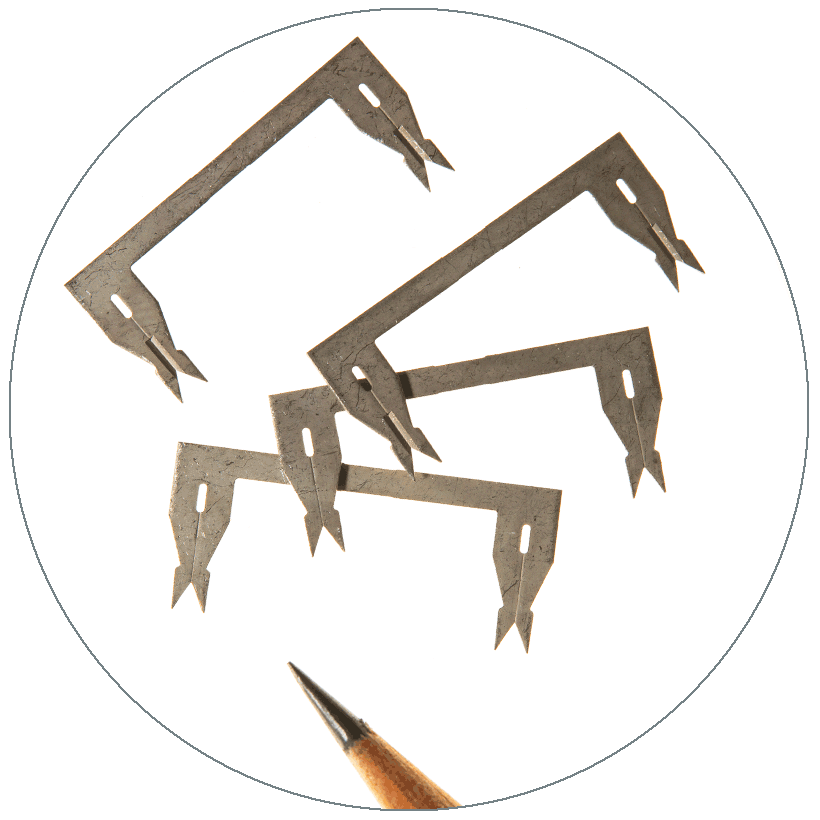

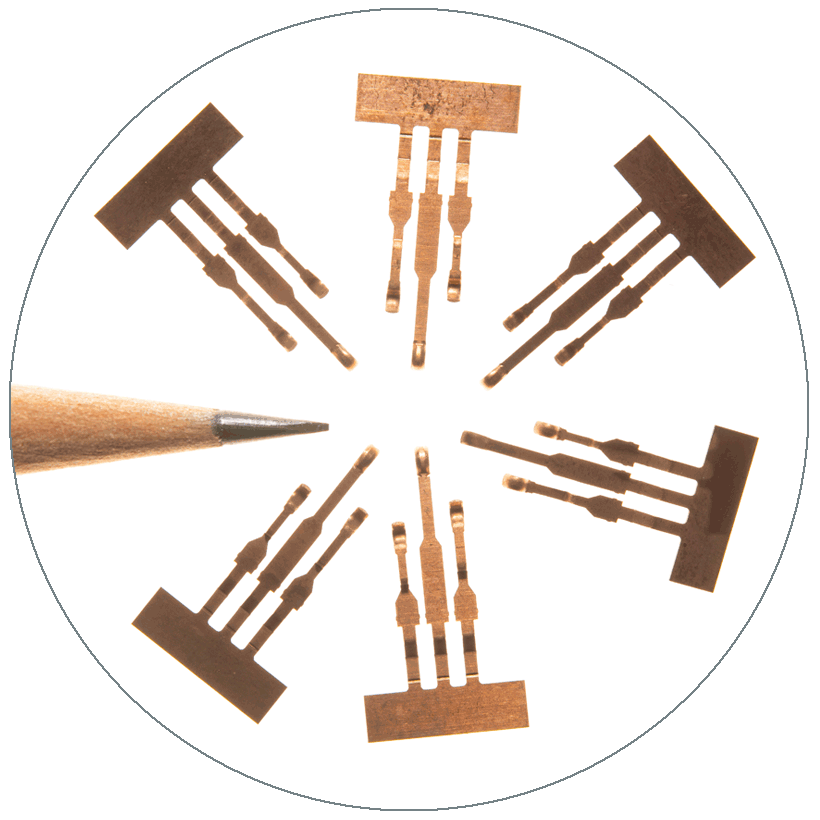

With Tooled components created, Ditron adheres to time-proven methods for die construction. We utilize spring strippers, split and ground (segmented) carbide die sections, carbide punches and carbide forms as needed. We also utilize 4 pillar aluminum die shoes with ball bearing cages, a technique that Ditron helped pioneer. This approach reduces tool construction time, facilitates any needed part revisions, and reduces wear on the stamping presses.

Lifetime Tooling quality and value.

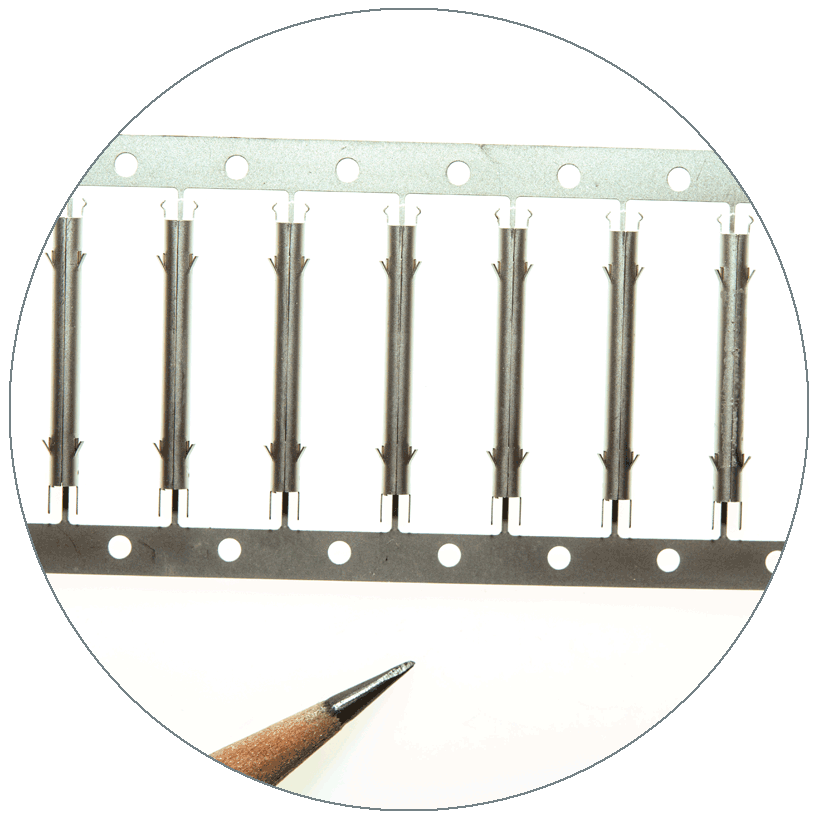

As a result, we build extremely robust, progressive dies capable of stamping parts at high speeds with precision consistency. This approach to die design and construction also means our customers never pay an annual maintenance or rebuild charge. Ditron tooling is built for perpetual life as long as the customer continues to purchase parts.

QUALITY CONTROL >>