Ditron Advantages:

Small, Miniature, and Micro-Miniature Metal Stamping with “Mega” Quality and Customer Service!

Ditron was founded on exceptional Micro Miniature Metal Stamping performance.

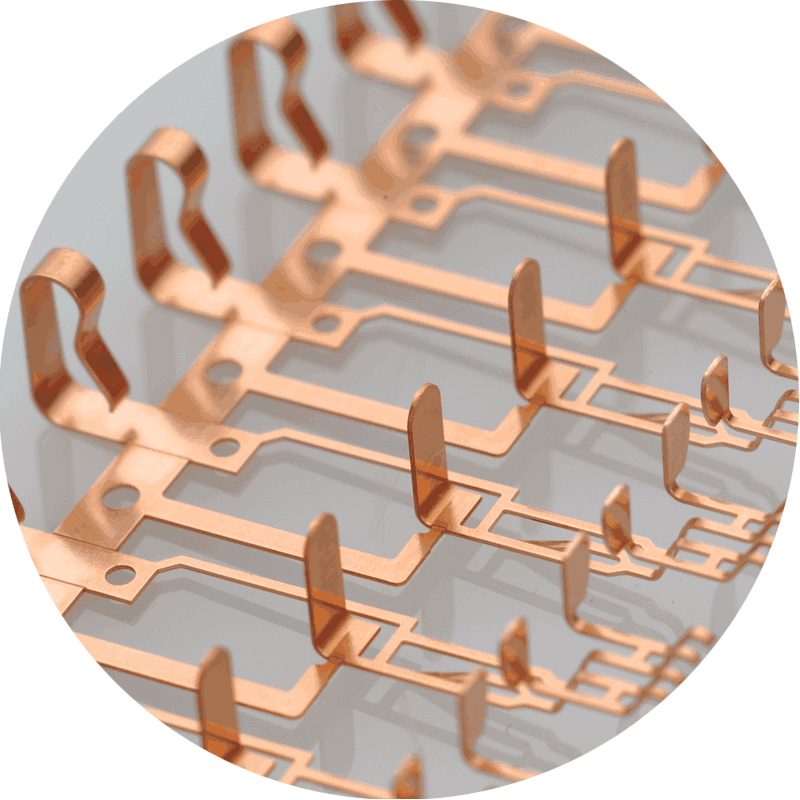

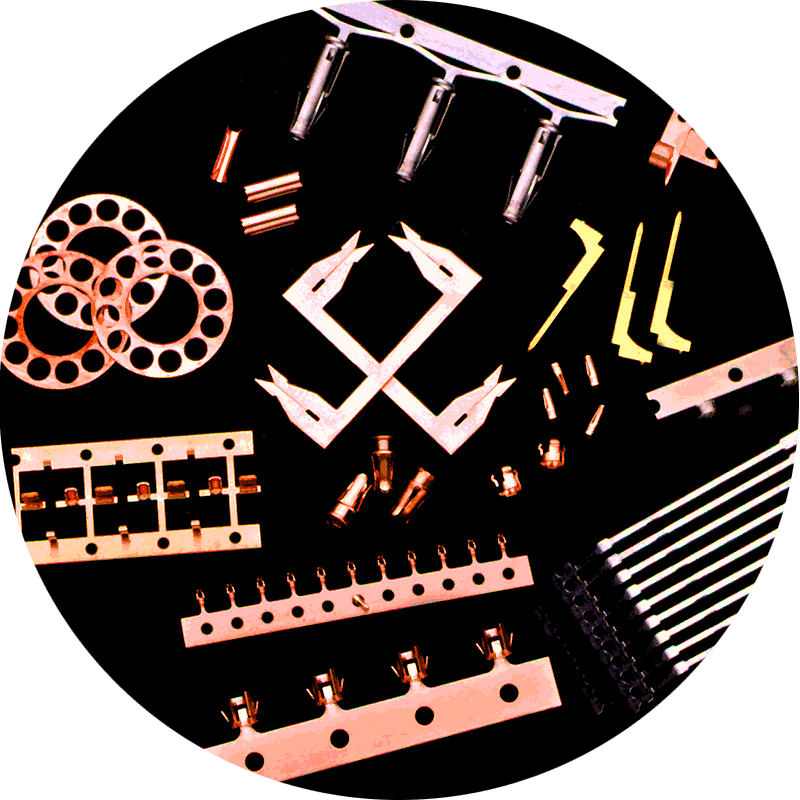

Small, Miniature, and Micro-Miniature Metal Stamping has become synonymous with the name “Ditron.” So has the term “world-class service.” Founded in 1963, our unique ability to achieve uncompromising micro miniature metal stamping accuracy led to our becoming a trusted supplier to companies world-wide. We stamp continuous form and loose parts used in electronic connectors, automotive, aerospace, telecom, medical, and other mission-critical industries.

Ditron: Micro Miniature Stamping innovation at every phase.

Ditron perfected a streamlined process for designing, building, stamping and heat-treating products custom-made to customers’ specifications. Micro Miniature Stamping innovation at every phase has been a key contributor to Ditron’s growth. Never resting on our laurels, we stay focused on our 3-point corporate mission:

1. Continually strive to improve stamping efficiency and speed

2. Maintain and improve part quality and integrity

3. Make every customer our #1 Priority through the “3 Rs:” Respect, quick Response, and challenge-solving Remedies

Ditron: A History of poineering advancements.

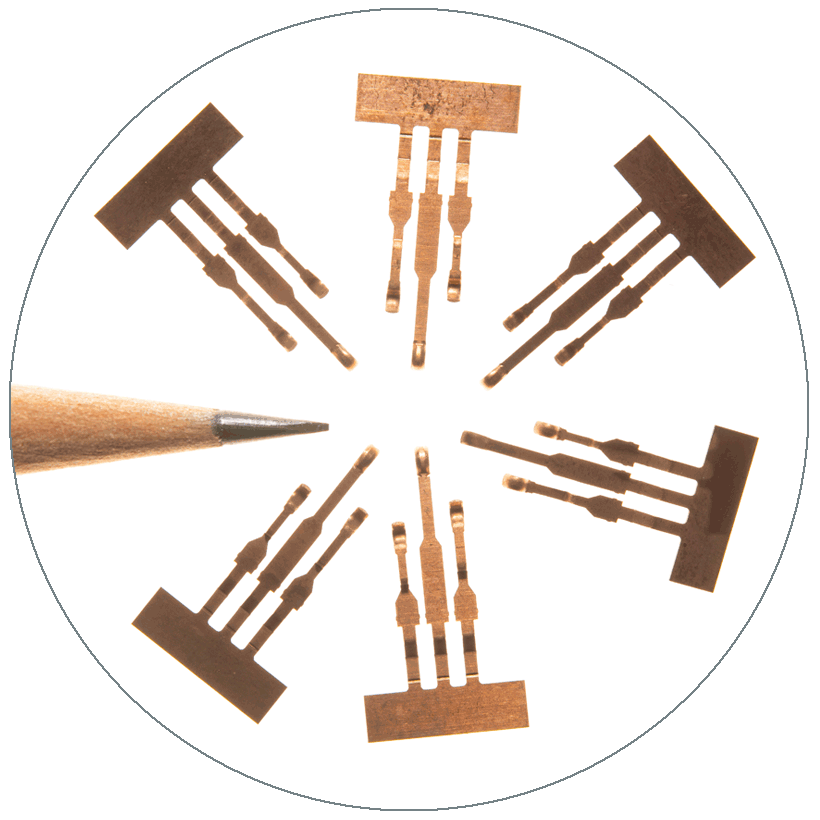

Historically, our mantra of “what can we do to improve” has pioneered and perfected techniques for stamping Micro-Miniature parts from thin gauge ferrous and non-ferrous metals, including Beryllium Copper. The result has been international recognition of capabilities that include lean “just-in-time” (JIT) delivery, and “zero defect” Quality Control.

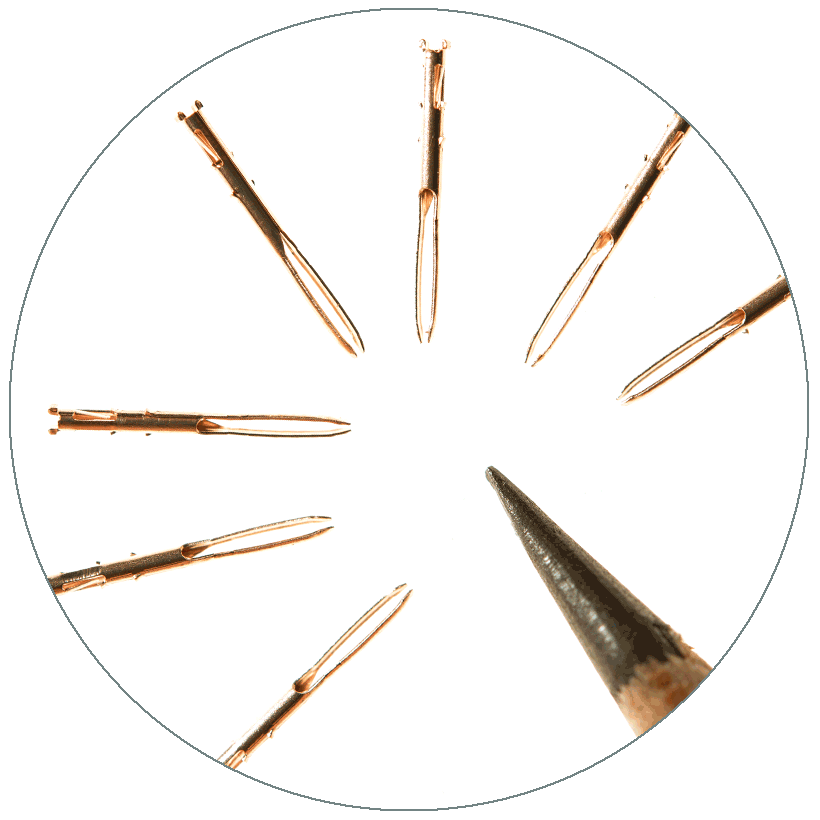

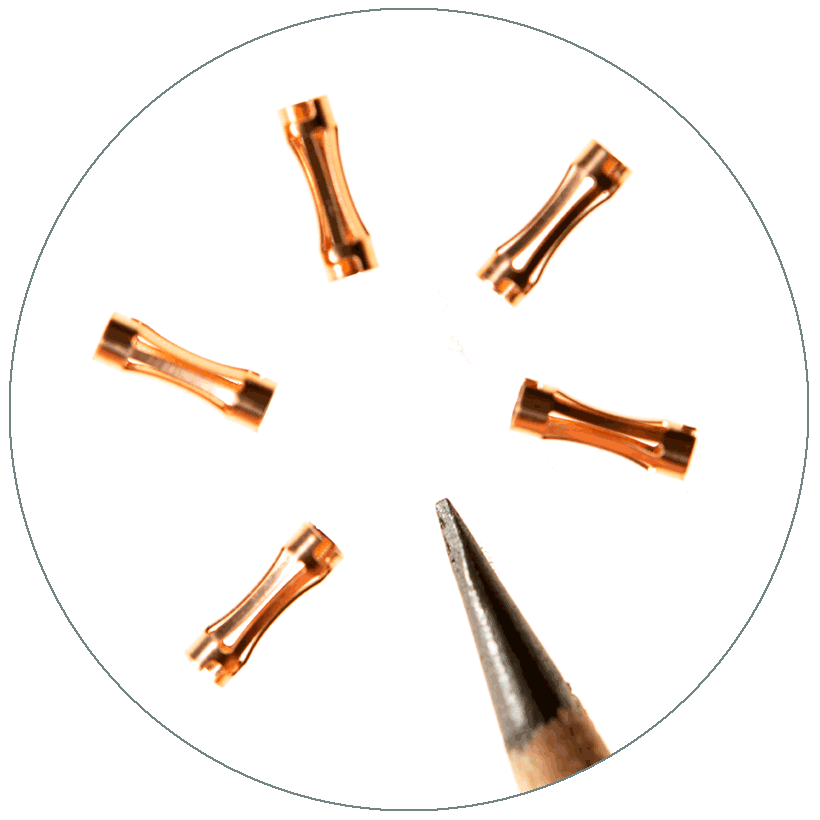

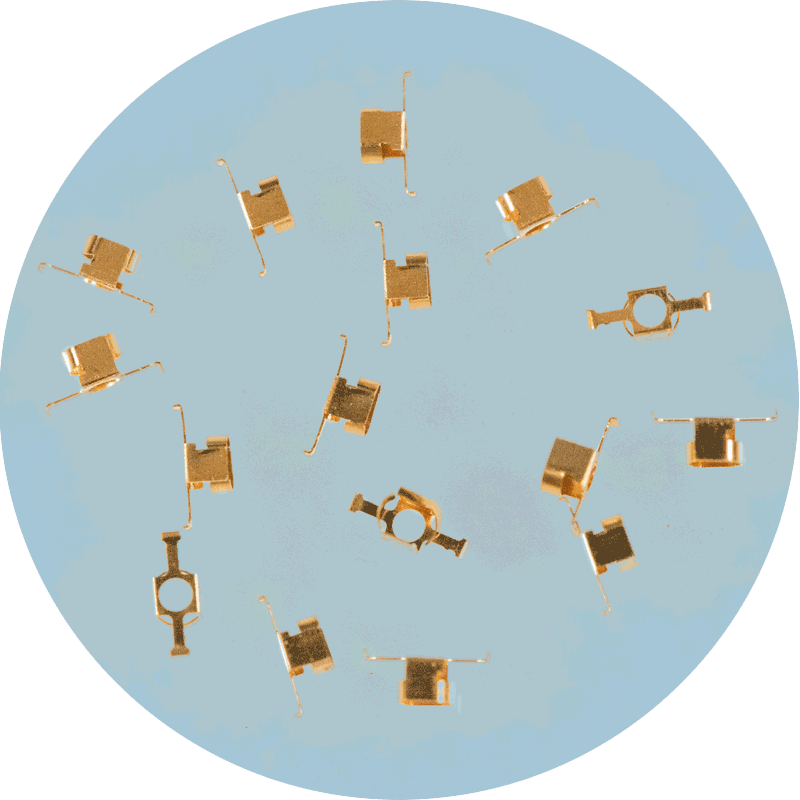

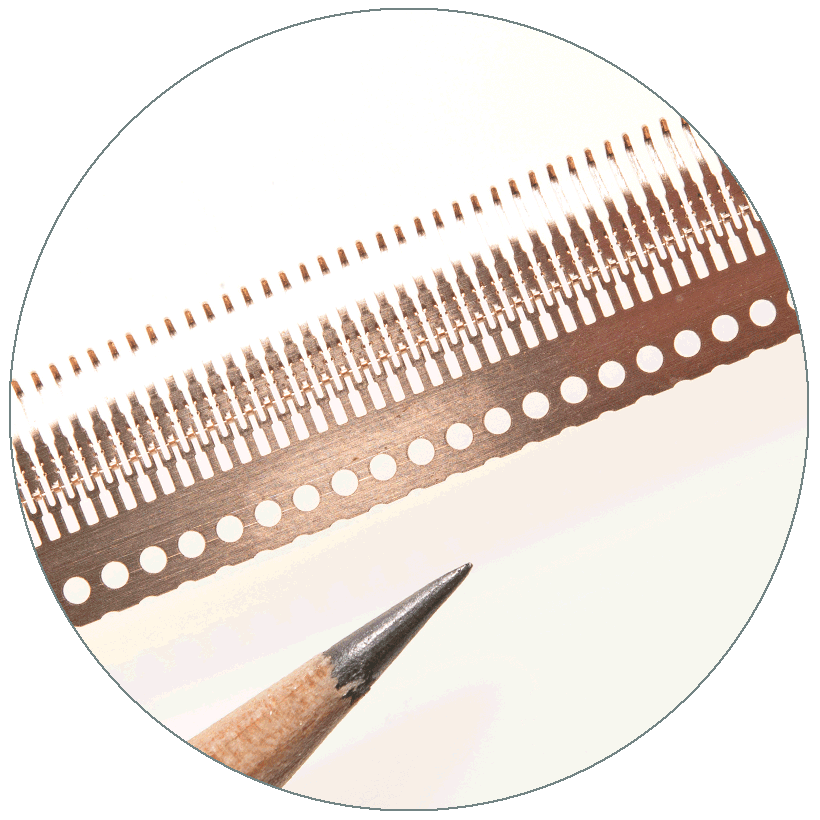

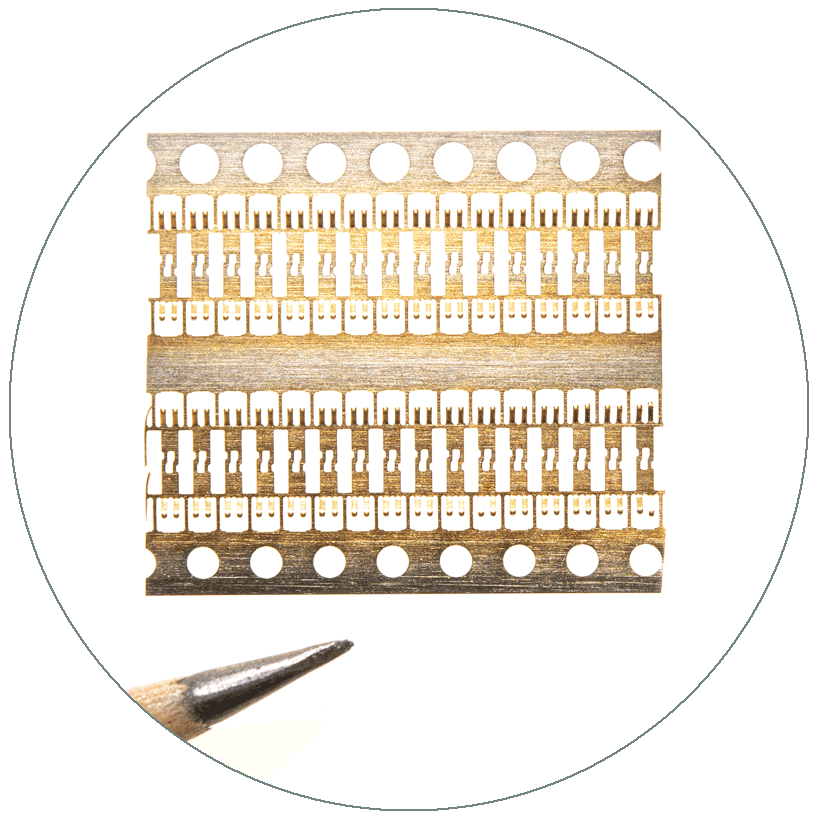

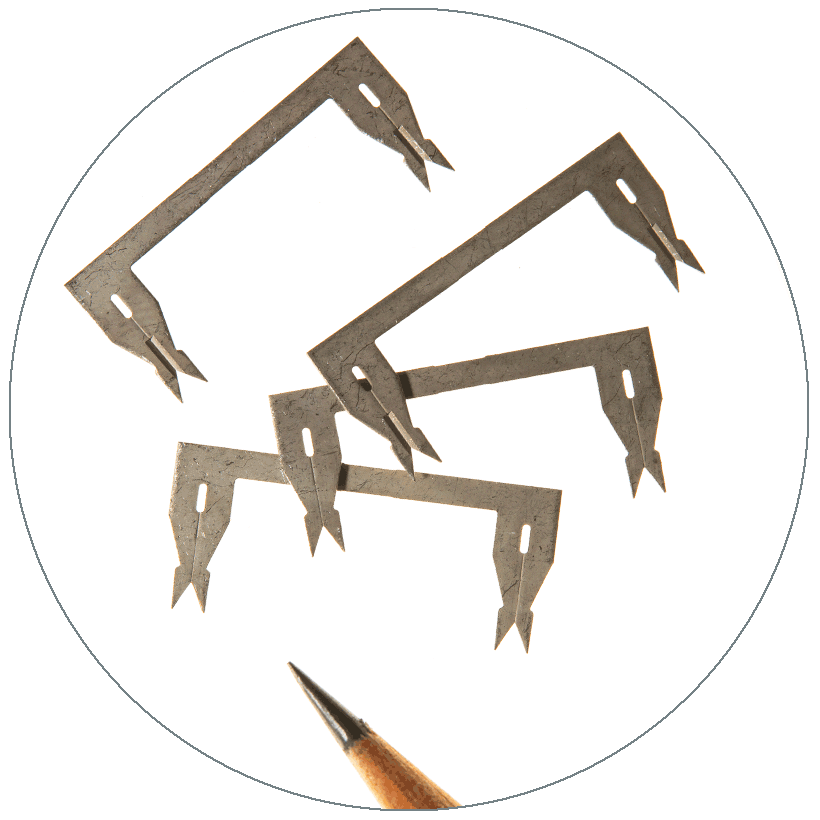

Ditron’s remedy-focused approach led to our creation of “Mosquito Clips.” These stamped electronic contacts continue to play a key role in the “microscopic-downsizing” that changed and catapulted the electronics world!

Ditron: unmatched customer service and support.

At Ditron, we attribute half our success to the Quality Assuring Processes we infuse into every step of the Precision Micro-Miniature Stamping process. The other half we attribute to always providing customer-first service and program support. Our team-oriented approach and early involvement provides savvy planning and clear, concise communications. As a result, customers realize pro-active advantages from part design, tooling design, and prototyping through inventory management, packaging, and delivery. Work with Ditron, and you gain a supply partner dedicated to ensuring total success for you and your project .

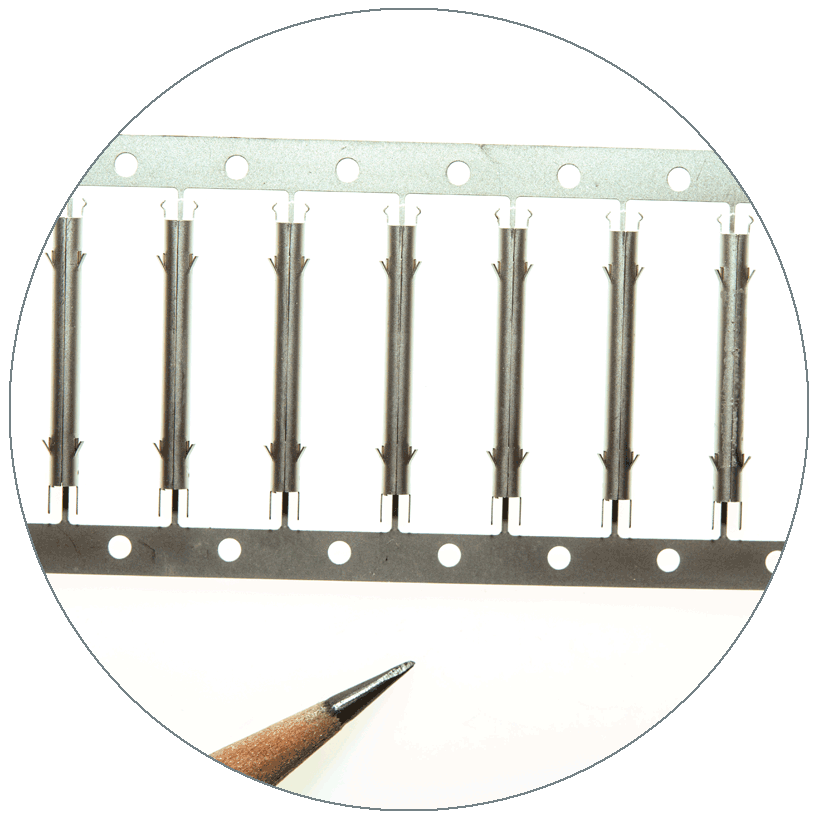

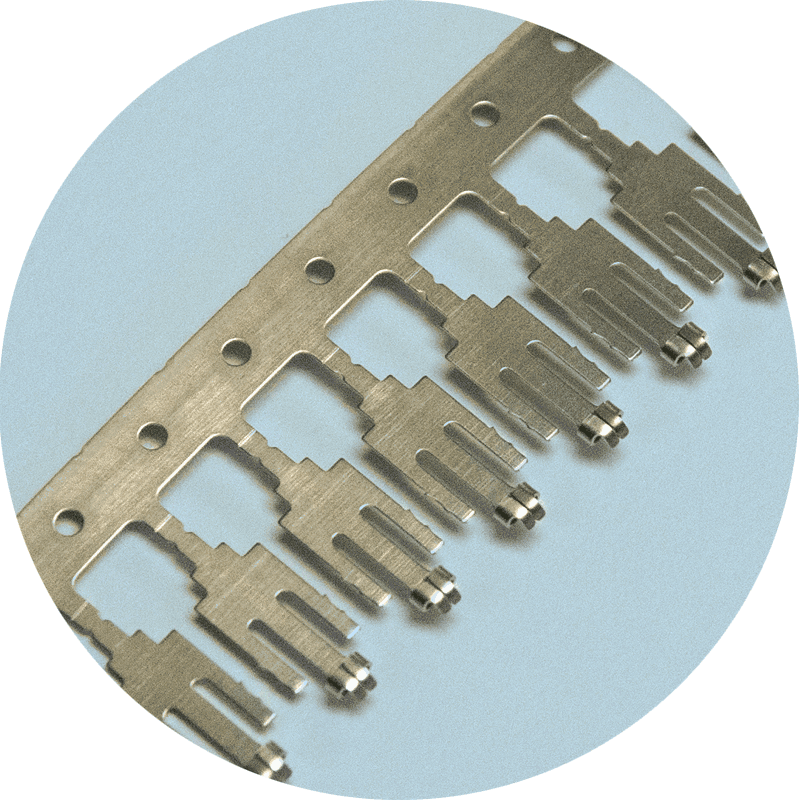

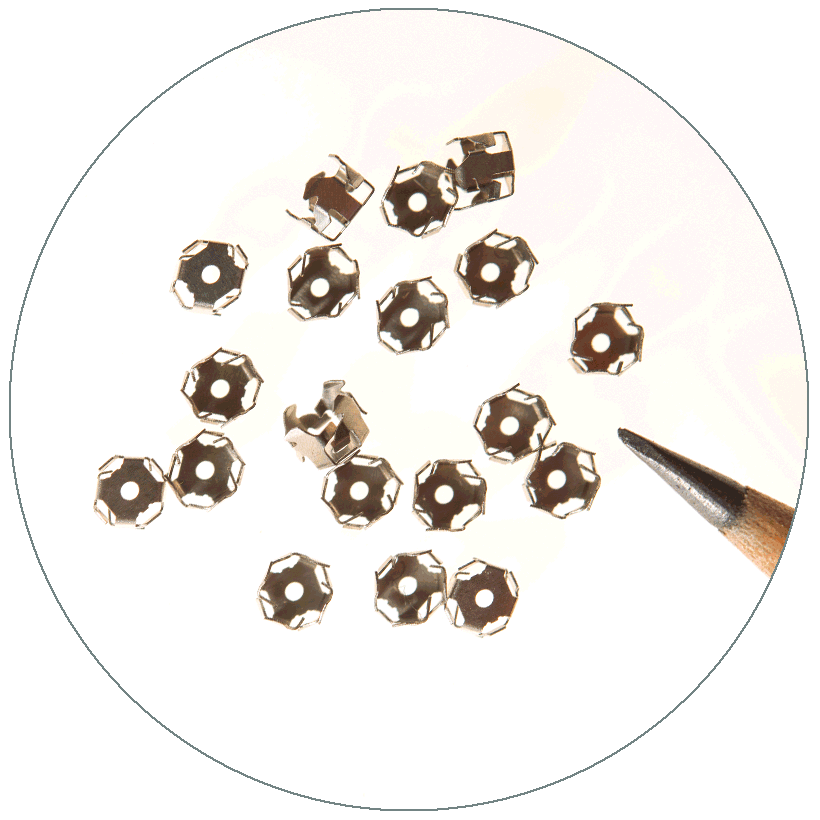

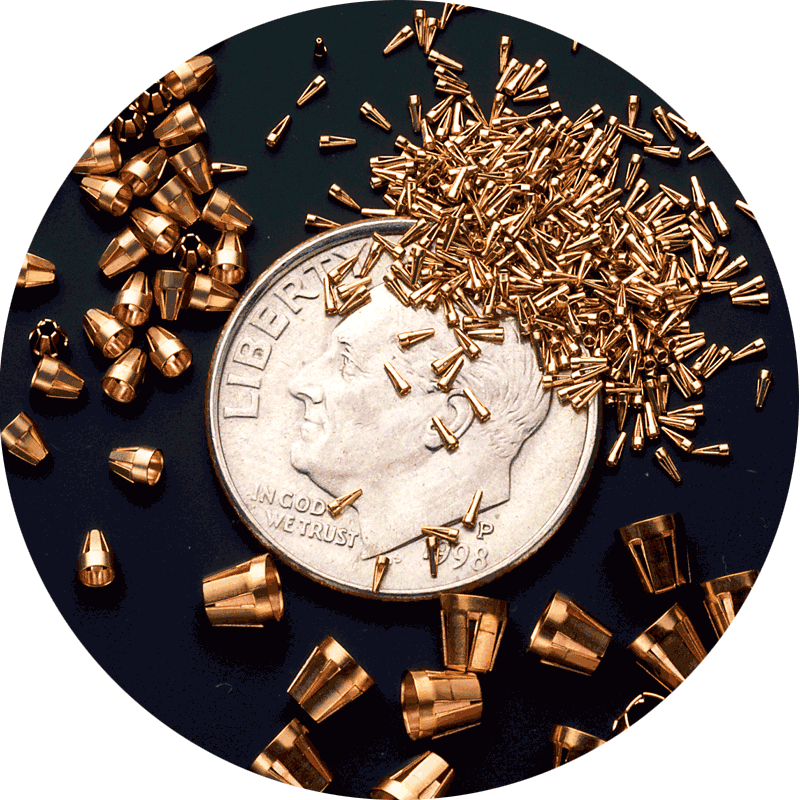

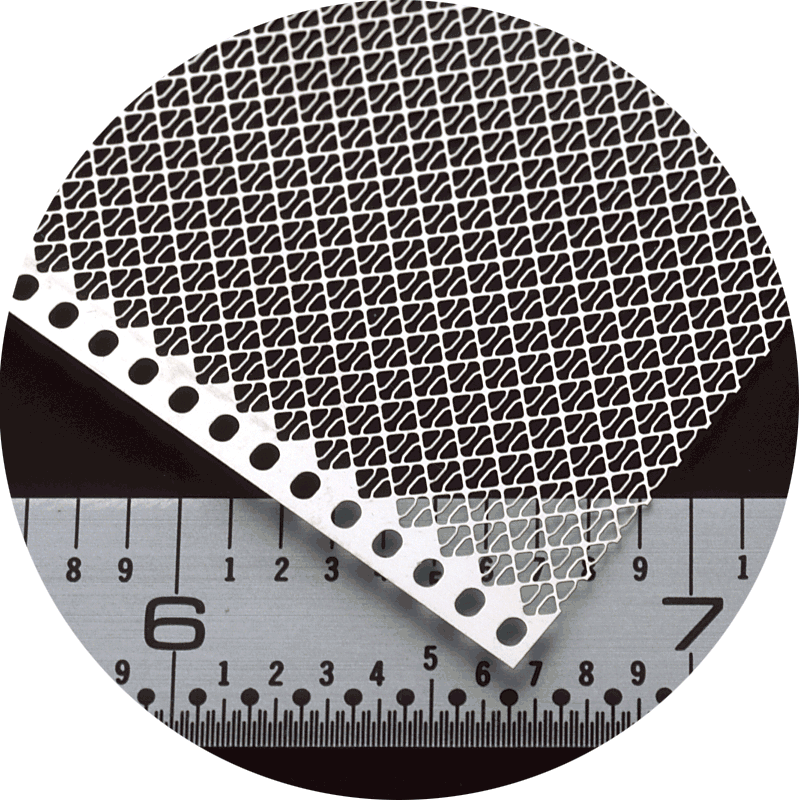

When you need small form factor parts, Stamped from material as thin as .0015 to 1/32 inch in thickness, you need Ditron!

Ditron Advantages Overview

- Product Innovation: Introduced stamped and formed 2, 3, 4 and 6 finger “mosquito clips” to the electronic industry

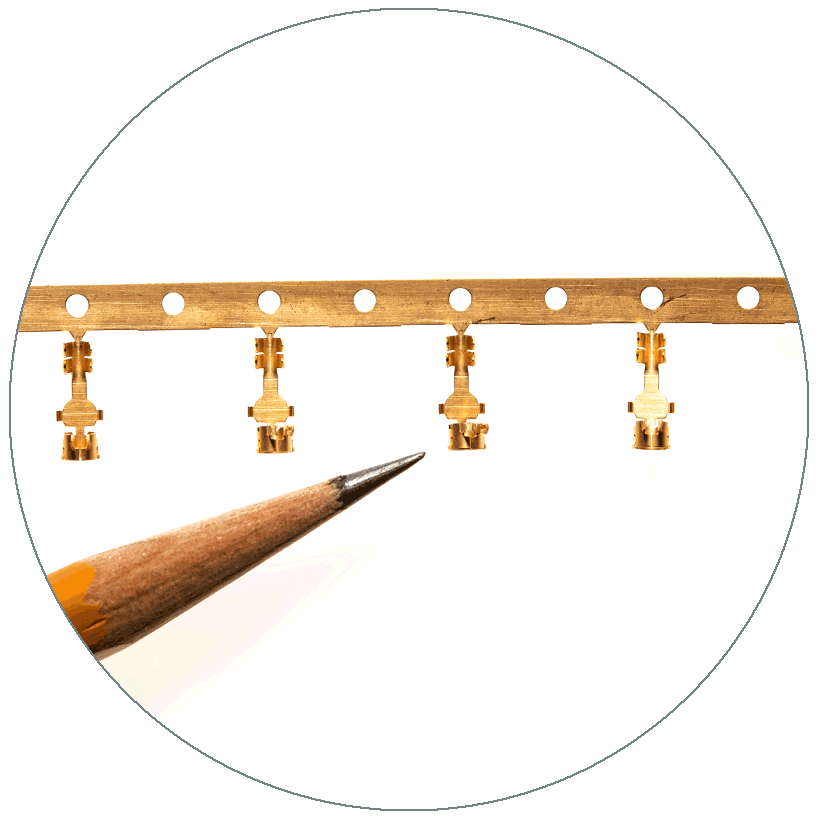

- Tooling Design: Design and build progressive die tooling for high-speed, high-volume production

- Tooling Expertise: Unsurpassed tool-building craftsmanship

- Prototype Development: Design, working prototype development, and refinement

- Registered Certification: Confirming ability to meet industry-mandated critical tolerances

- Computer Accuracy: Completely Integrated CIM (Computer Integrated Manufacturing)

- Success-Focused Support: Courteous swift, proactive customer support

- Material Supply: Raw Material inventory and ongoing supply dependability.

- Agile Flexibility: Quickly responsive to accommodate program changes and updates

- Coiled Stock Stamping: Continuous attached parts, finished and packaged to exacting spec.

- Loose Piece Stamping: Finished and packaged fun bulk according to your volume needs.

- One-on-One Relations: Delivering concept-to-delivered-product accountability

- Quality Assurance: integrated at every phase of planning, production, and supply

- Lean-Stamping Focused: Continually looking for ways to improve production efficiency.

- Value Add: Part Finishing, Inventory Management, JIT staging, and more.