Tooling Maintenance & Storage

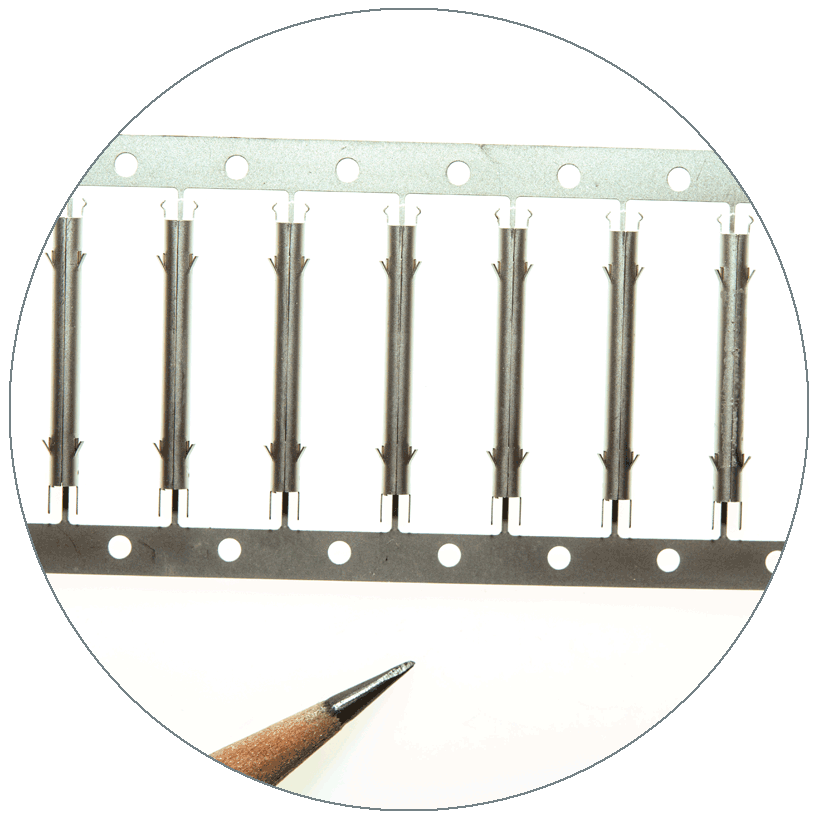

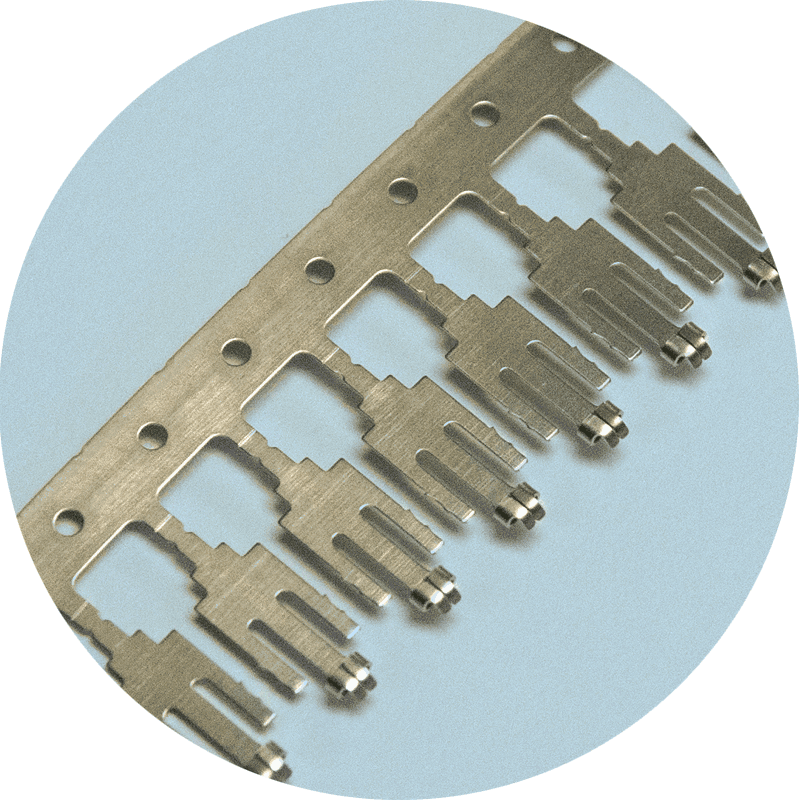

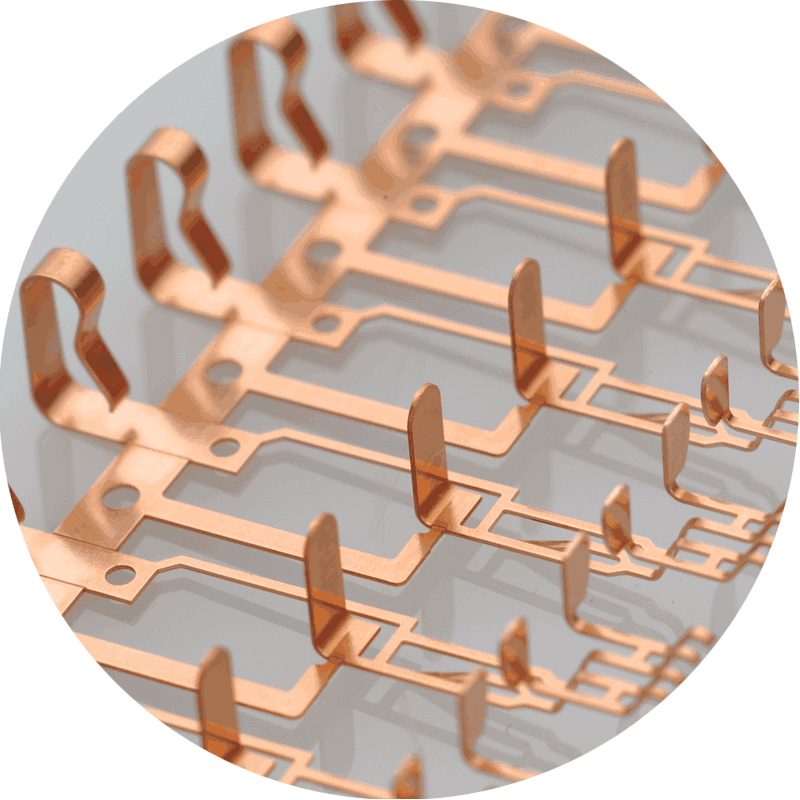

Automated Tooling maintenance to reduced program cost.

Ongoing Tooling maintenance at Ditron is another element supported by our integrated CIM (Computer Integrated Manufacturing) system. If a variance in die performance is detected, our tooling engineers can zero in on the affected elements, and then download to our EDM center to recreate new tooling with “lights out” efficiency and exact-replica accuracy. As a part-purchasing customer, you are never charged for this quality assuring maintenance.

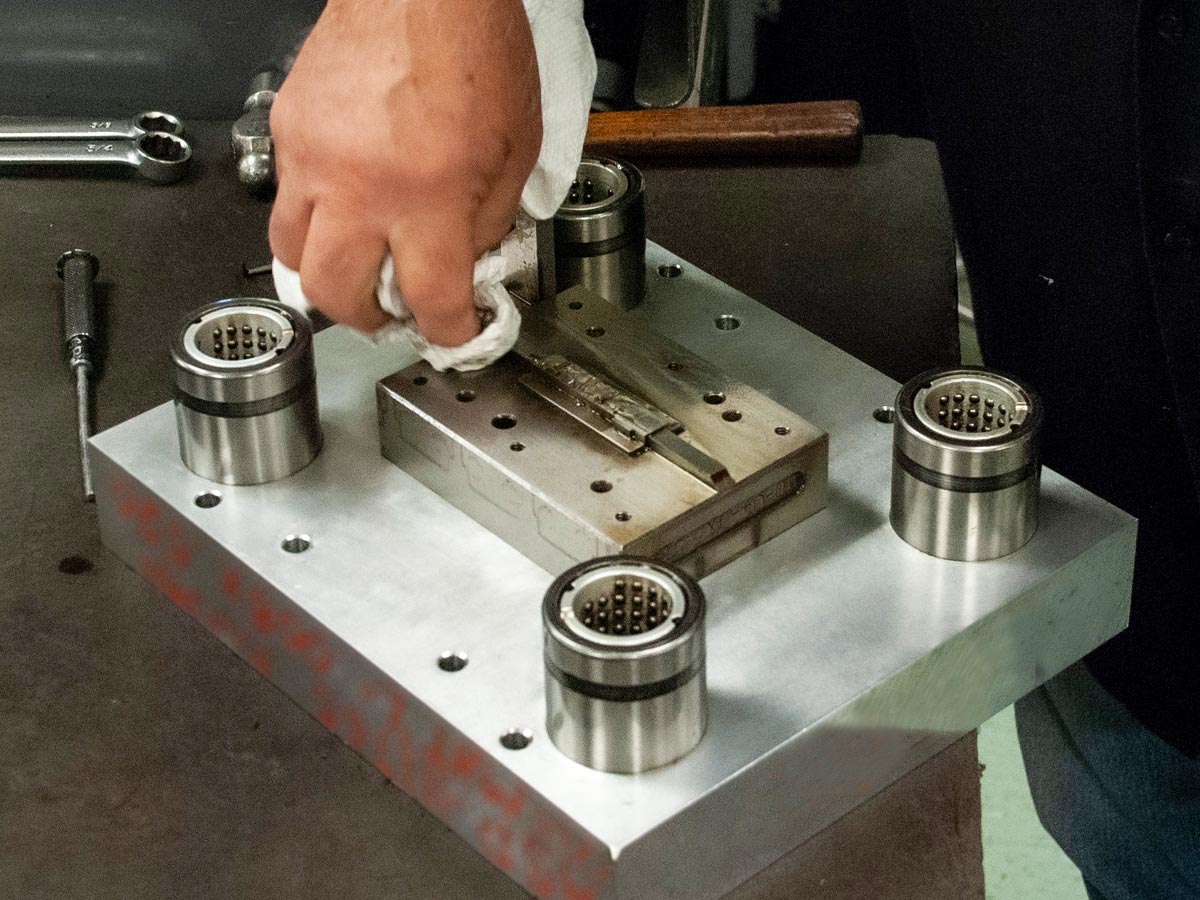

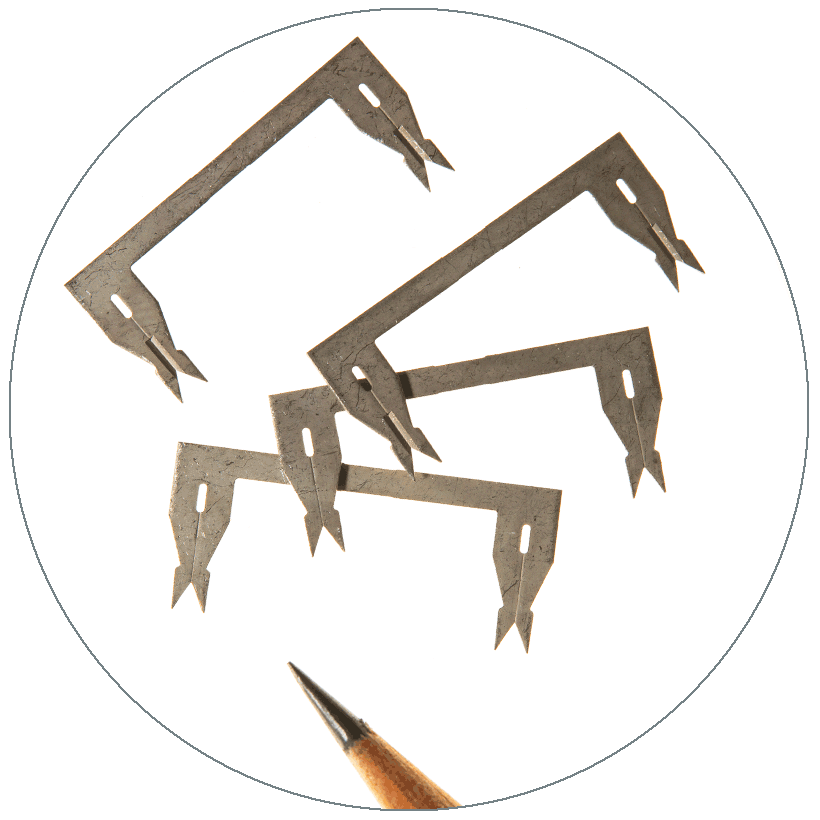

Tooling storage.

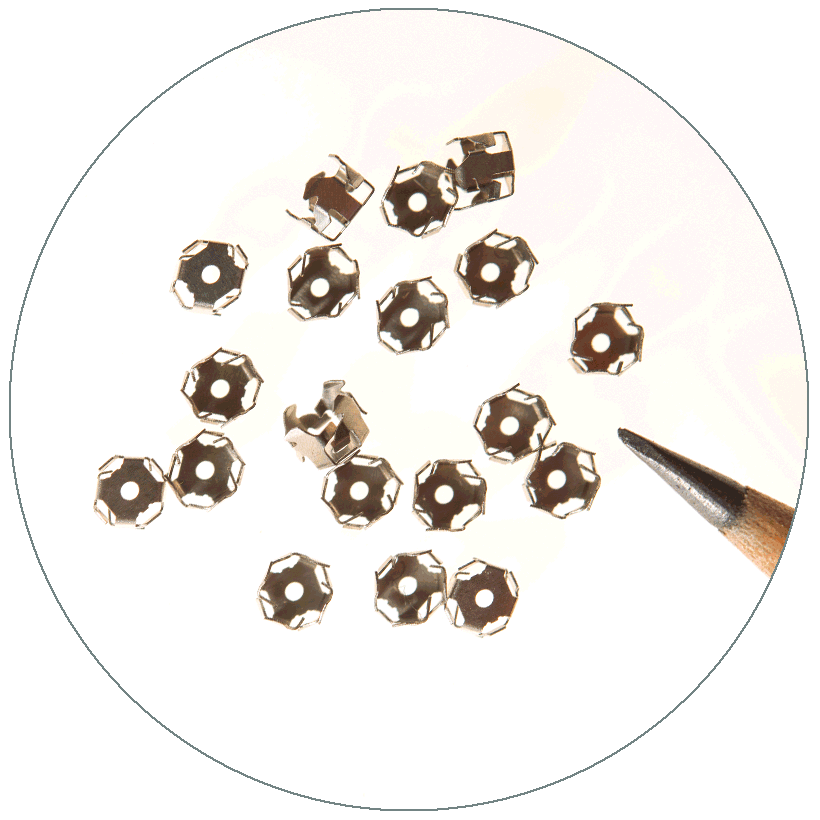

Secure Storage of Tooling after scheduled production is another value that Ditron customers enjoy. When a stamping program ends, we clean, treat, catalog, and carefully store the tooling for convenient future access. We also document and archive samples of the parts or components that the tooling generated at key points throughout its production cycle.