Ditron Facility & Equipment

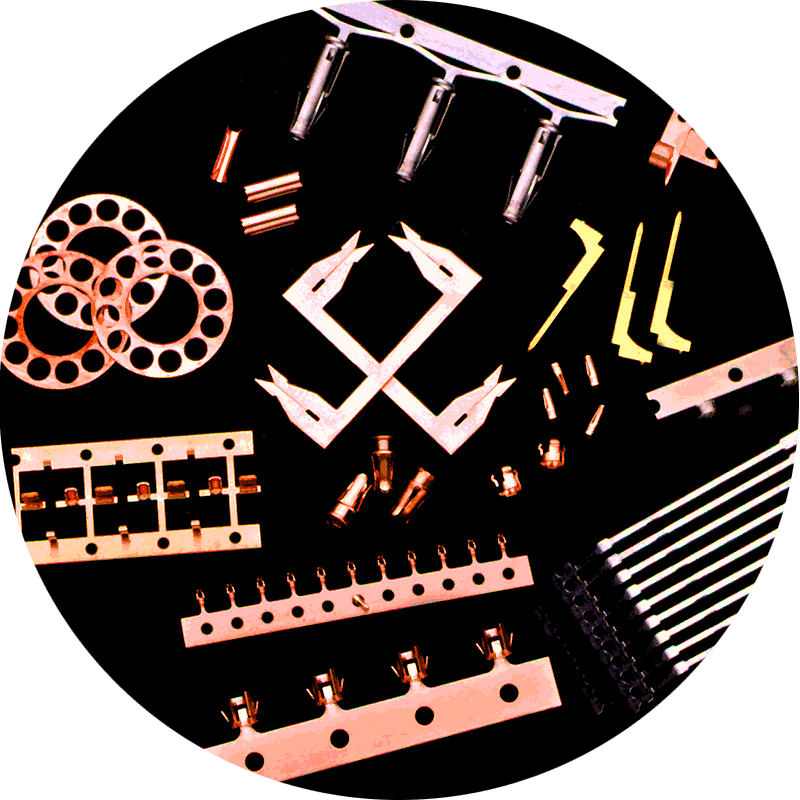

Ditron was designed from the ground up specifically for precision stamping.

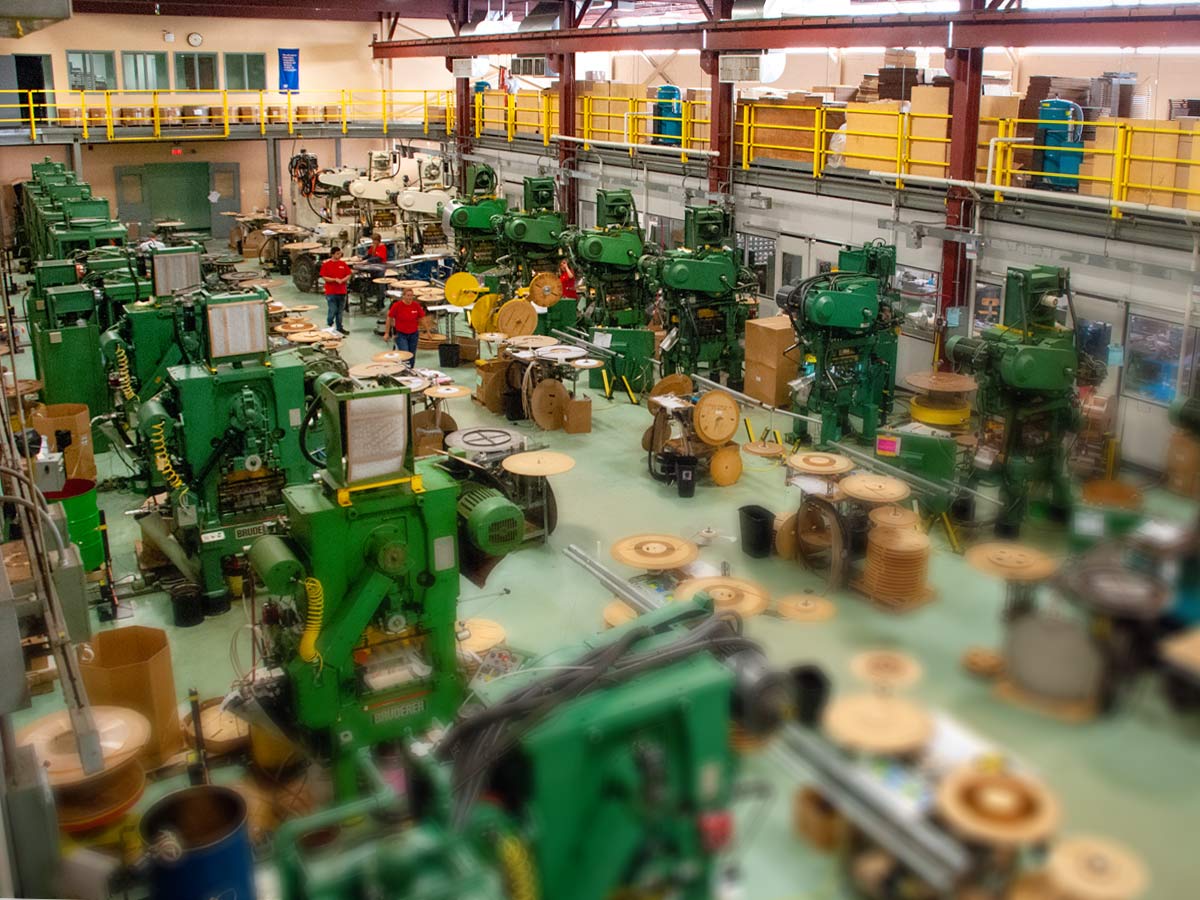

Ditron Facility Equipment: our expansive 32,000 s.f. facility was constructed specifically to support precision-stamping success and lean manufacturing practices. As a result, our strategically engineered plant footprint delivers turnkey convenience while ensuring uncompromising speed, efficiency, and Quality Control at every stage of the stamping program.

BRUDERER stamping presses for unsurpassed accuracy and reliability.

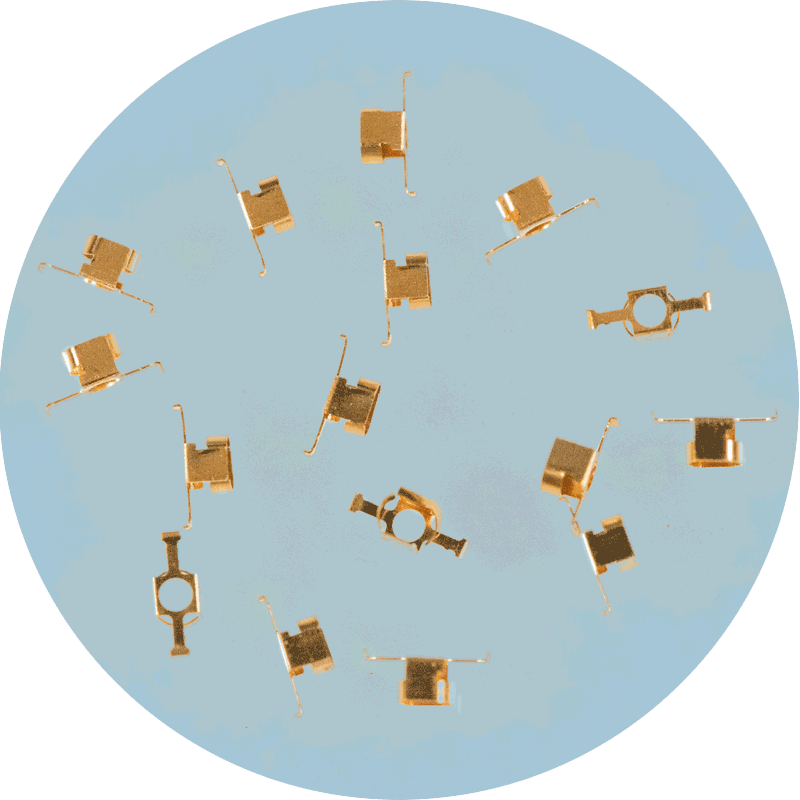

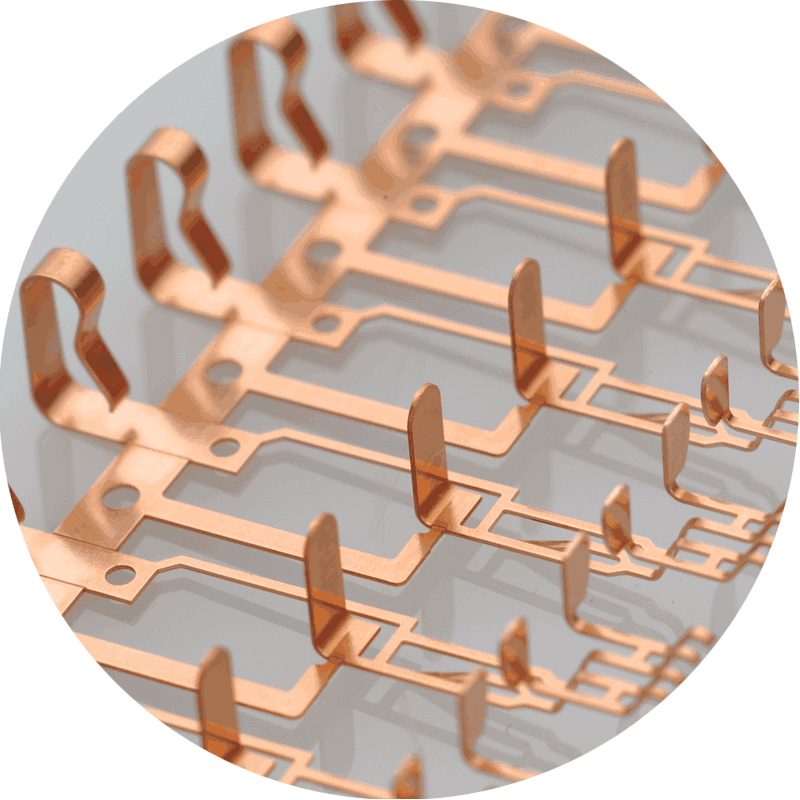

Precision Stamping the highest quality parts requires using the highest quality Stamping machines. So we exclusively use BRUDERER Presses because of their proven ability to deliver maximum output with the utmost precision. Featuring balanced press load distribution, minimal bearing clearances, and super-effective lubrication systems, BRUDERER presses are industry acclaimed for long-life and reliable, consistent performance.

Our main Stamping Floor houses more that 2 dozen BRUDERER presses with stamping forces ranging from 22 to over 30 tons. These machines also provide stamping speeds ranging from 100 to 1,600 strokes per minute!

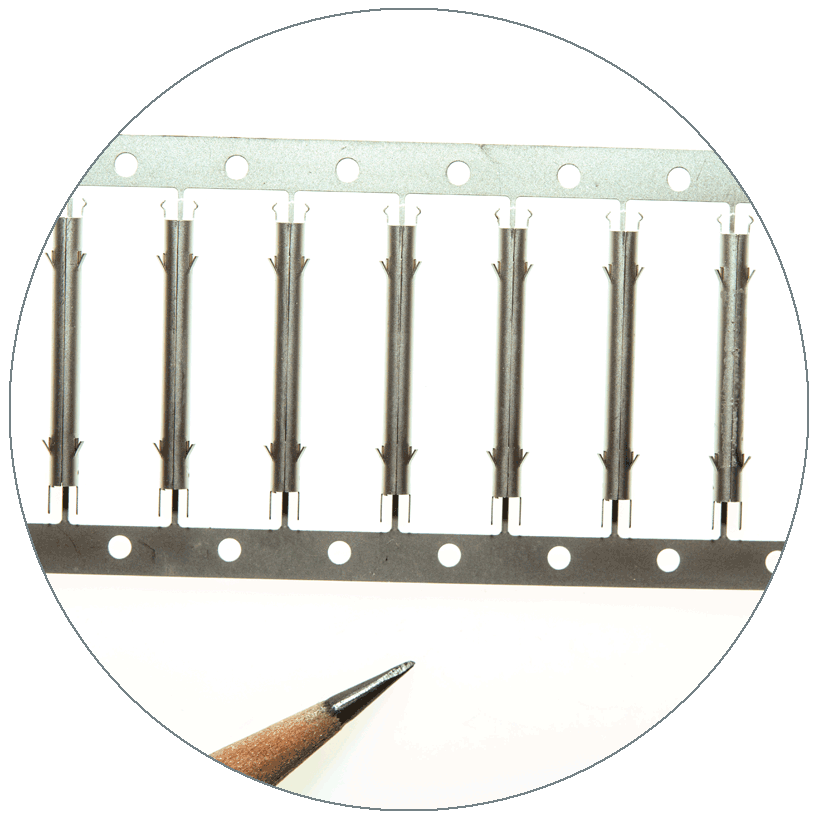

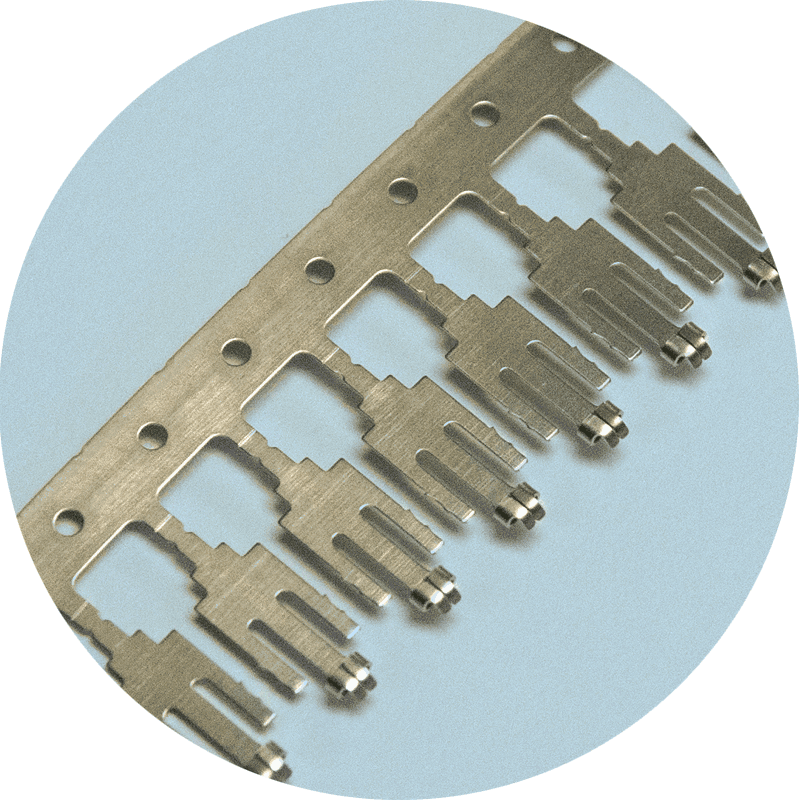

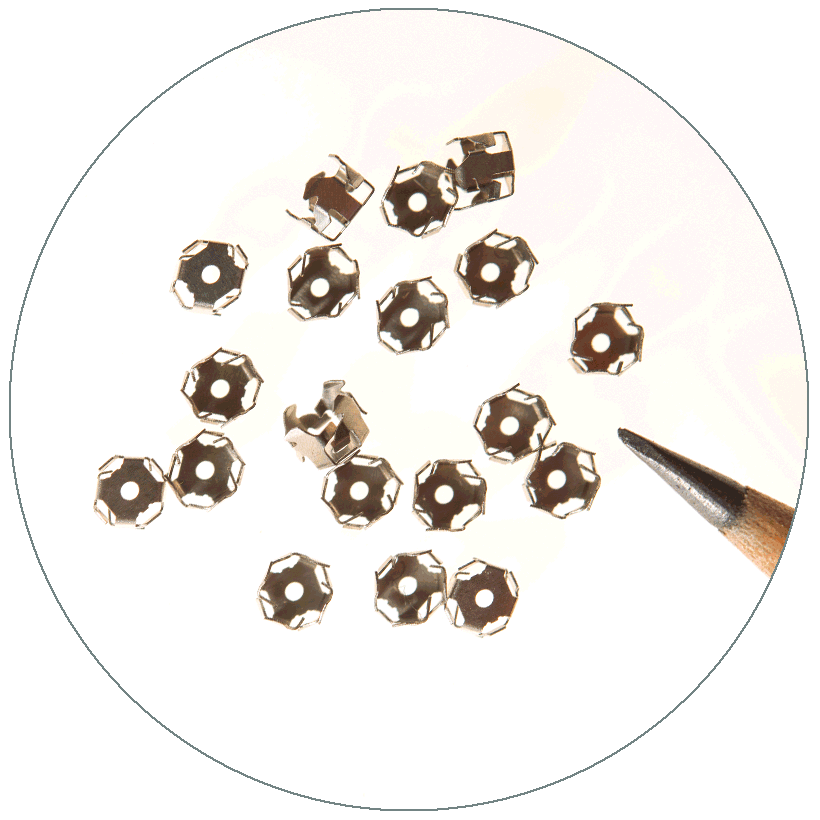

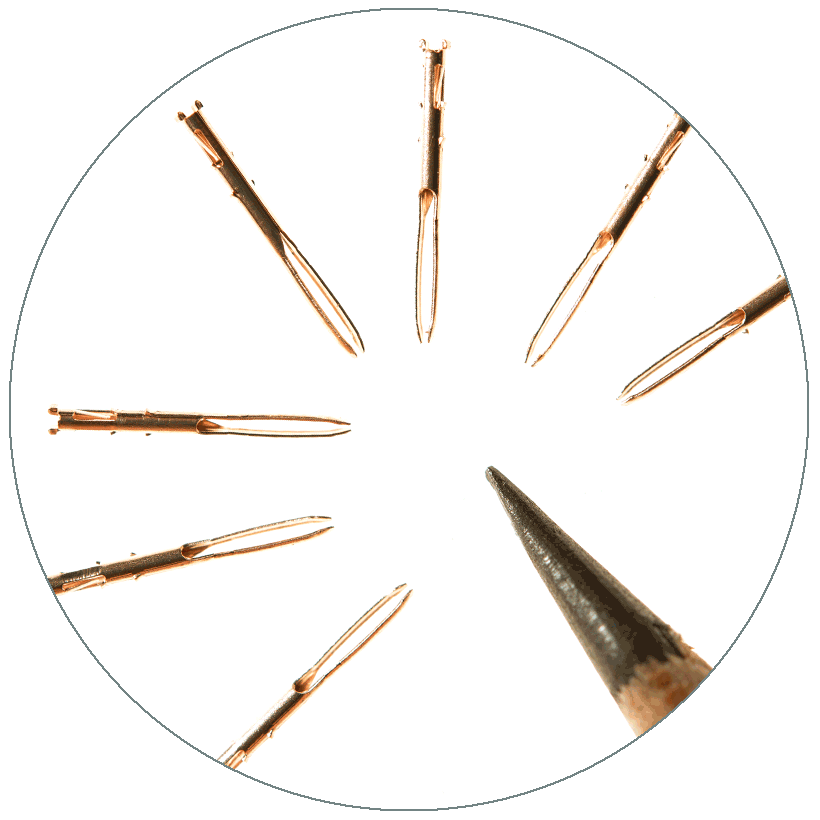

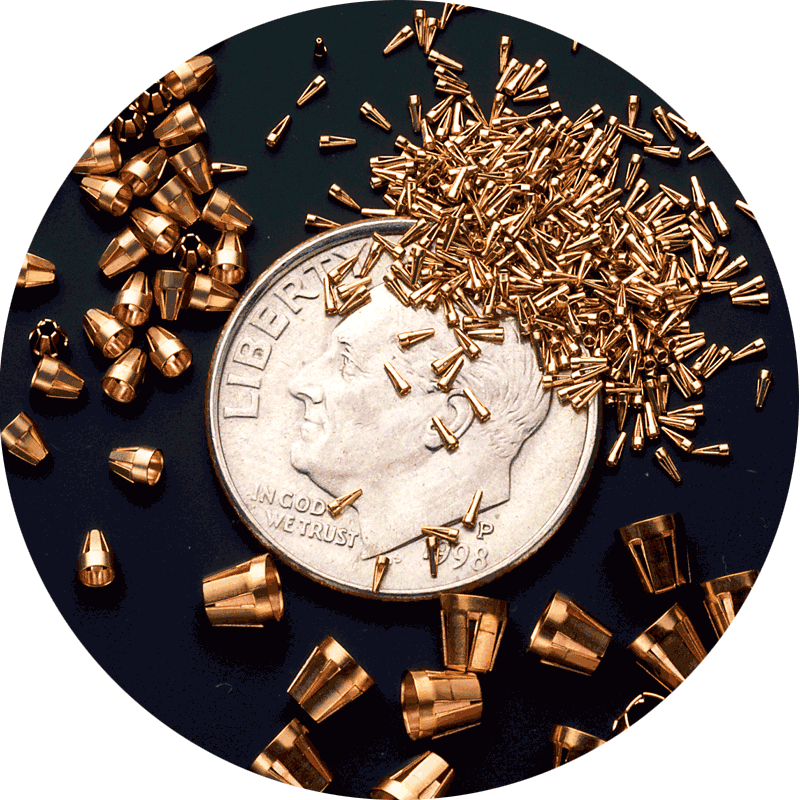

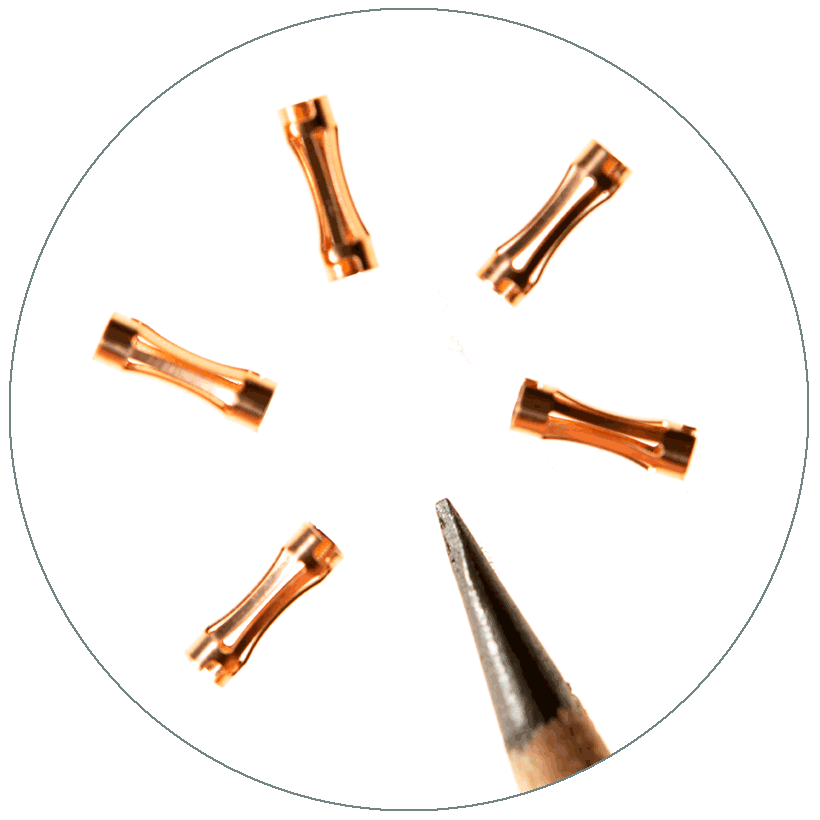

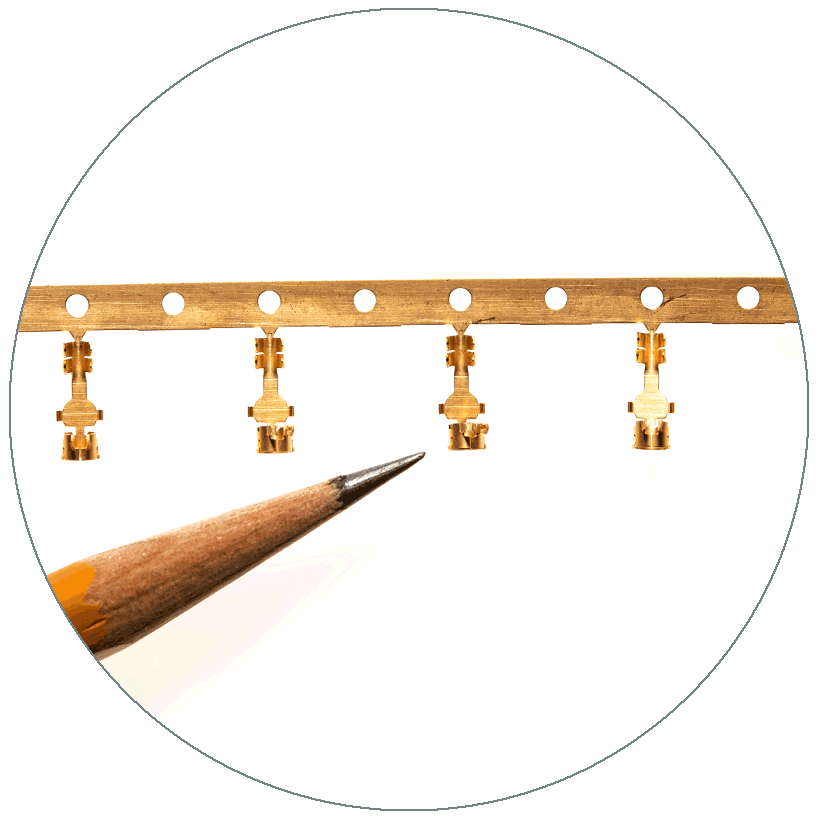

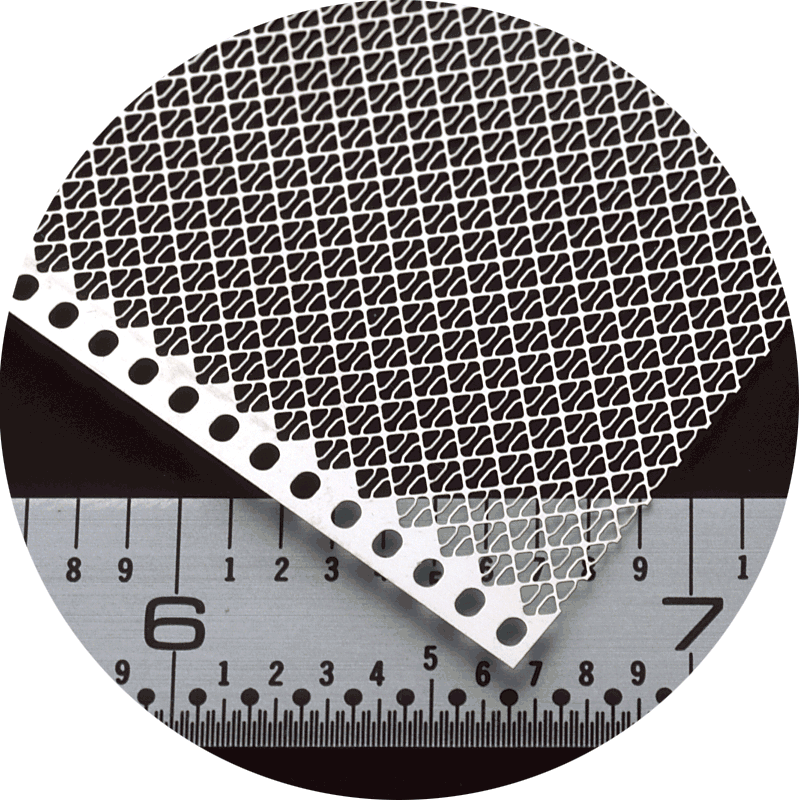

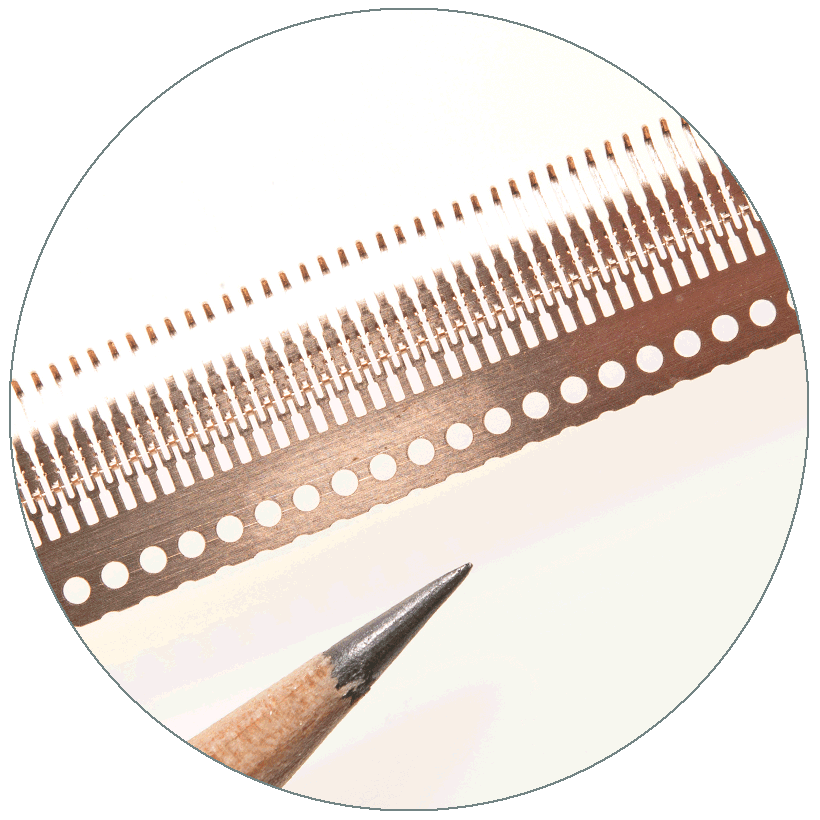

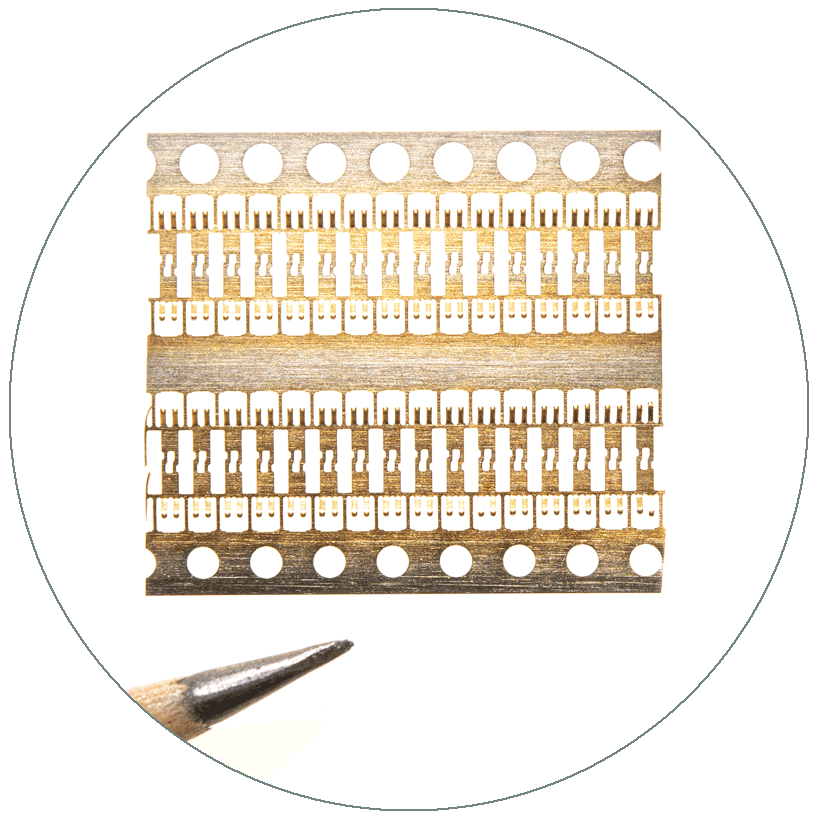

Combining Bruderer Press capabilities with Ditron’s innovative, thin-gauge material processing methods allows us to stamp dimensionally repeatable parts at incredible High Speeds from batch to batch in small quantities, or through the run of high-volume precision metal stampings.

Experience a closer look at Ditron’s facility and equipment.

Want a closer look at our Stamping floor, stamping presses, and facility? Taking our Virtual Video Tour is a great way to gain a quick overview of the stamping advantages Ditron delivers!

Stamping Equipment Overview

- Dozens of presses ranging from 22 to 30 tons (219 to 298 kN)

- Reel to reel, bulk loose piece, and stacked production capabilities

- 7-day production capability | Lights-Out production on certain projects

- Super High-Speed stamping (100 to 1,600 SPM)

Stamping Support Overview

- Dedicated tooling, Maintenance and Die Storage

- Dedicated Inspection & QA department

- Highly trained and experienced Press Operators

- Tooling Design Engineers with vast experience

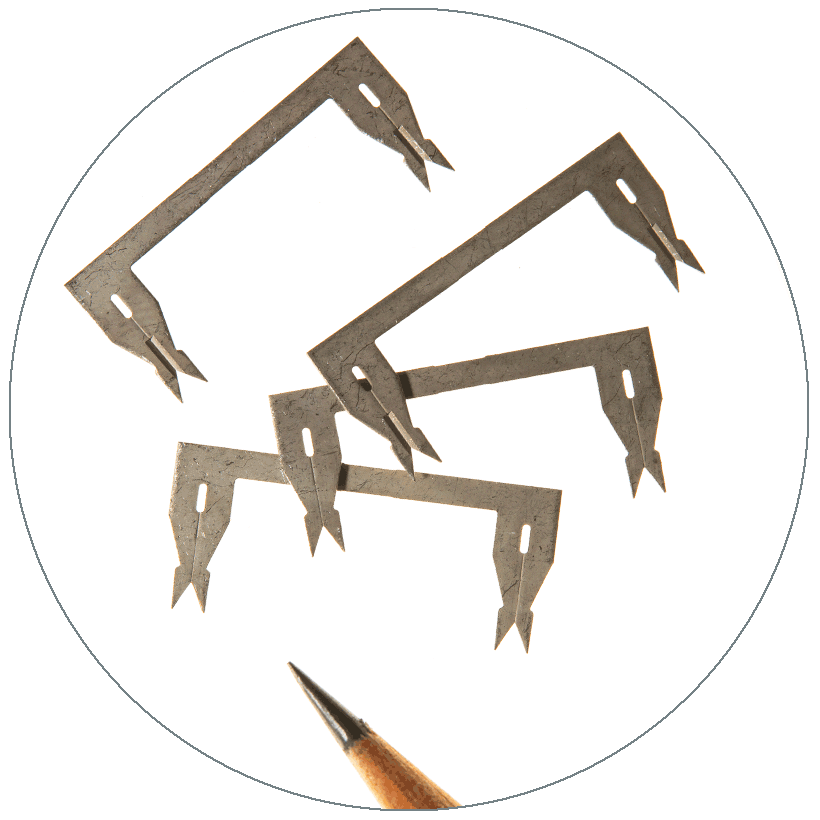

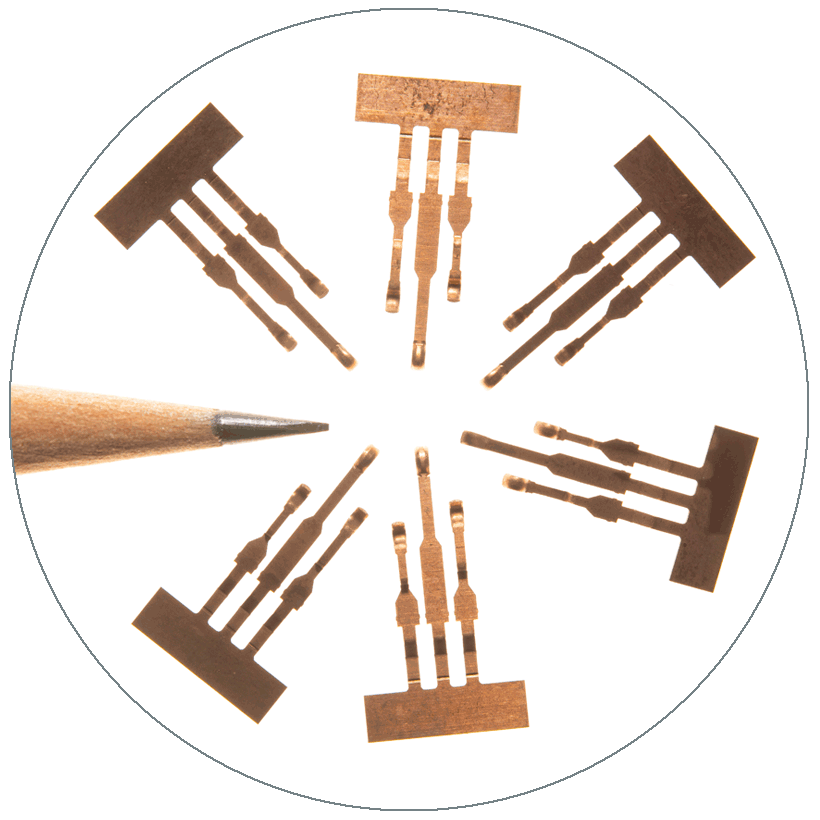

- Master Die Makers and Tool Makers experienced with Micro-Miniature precision parts

Value-Add Stamping Advantages

- Cad-equipped Design & Engineering department

- 4,000 s.f. inventory staging area

- Multi-station, optical, Comparator Inspection Lab

- Expansive raw Materials storage area

- Tumbling and Finishing department

- Isolated, clean Packaging & Shipping department