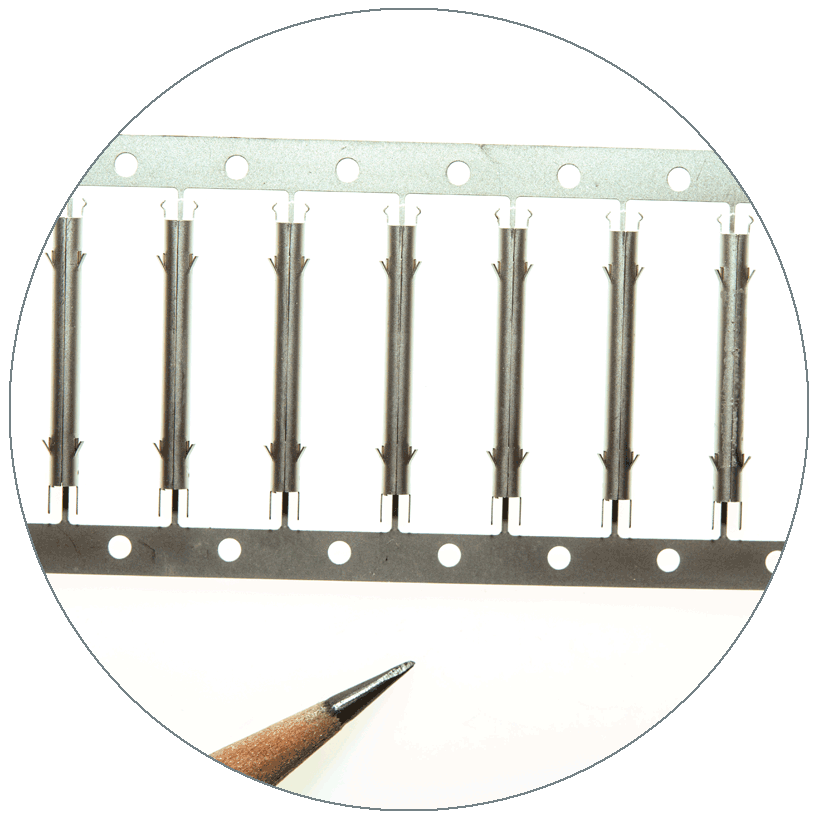

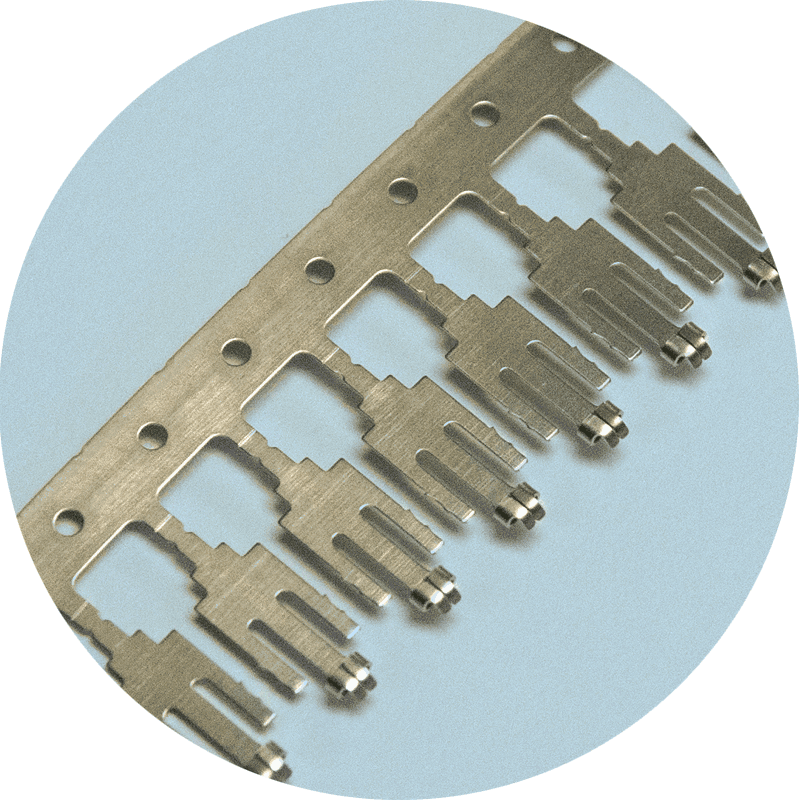

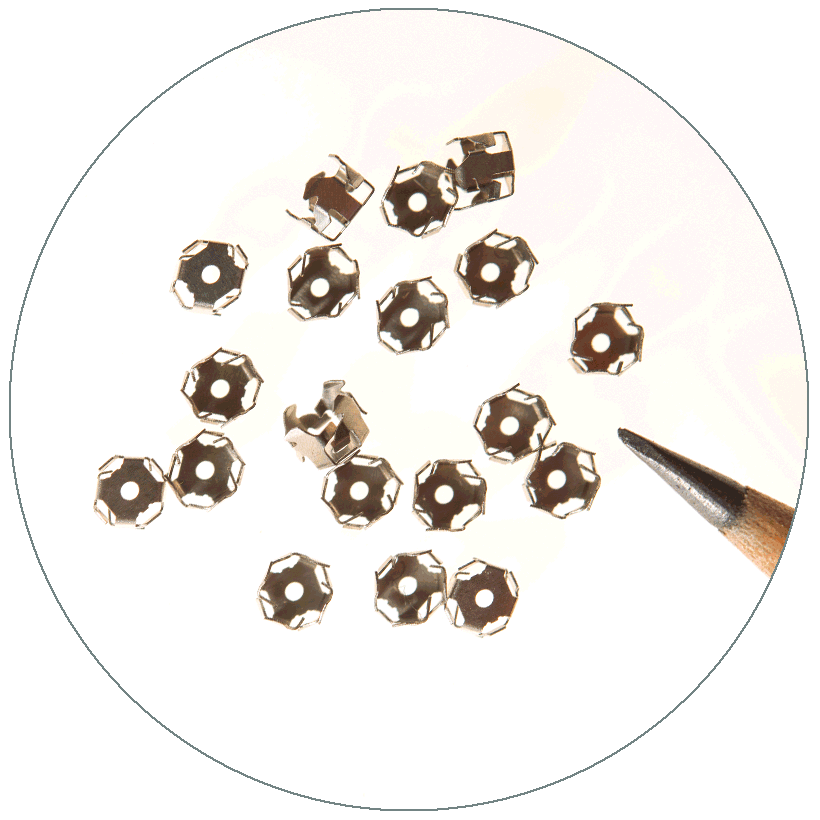

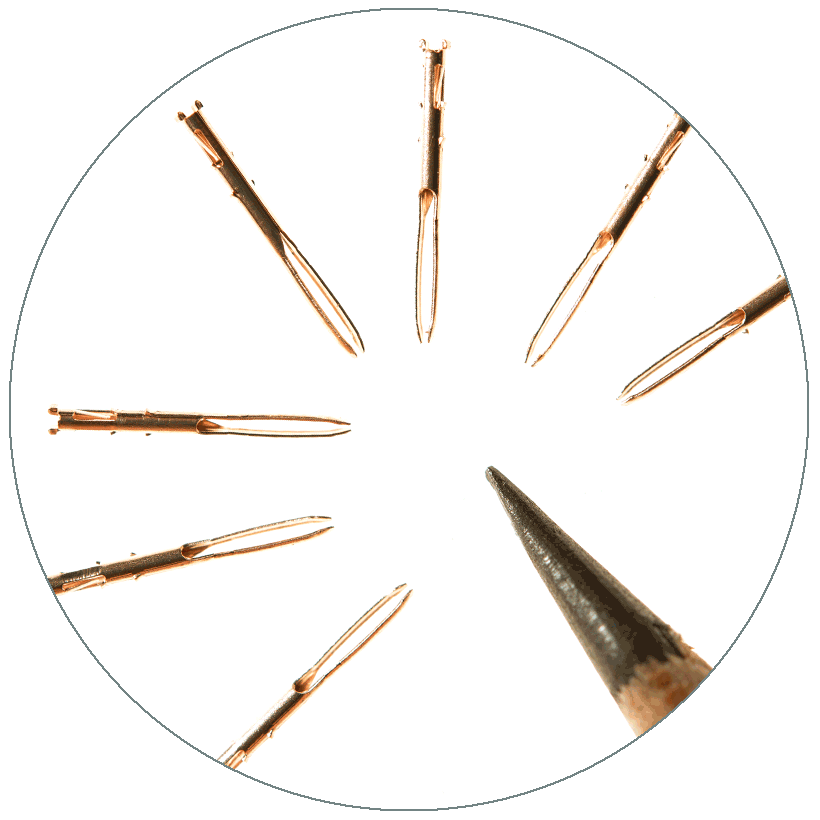

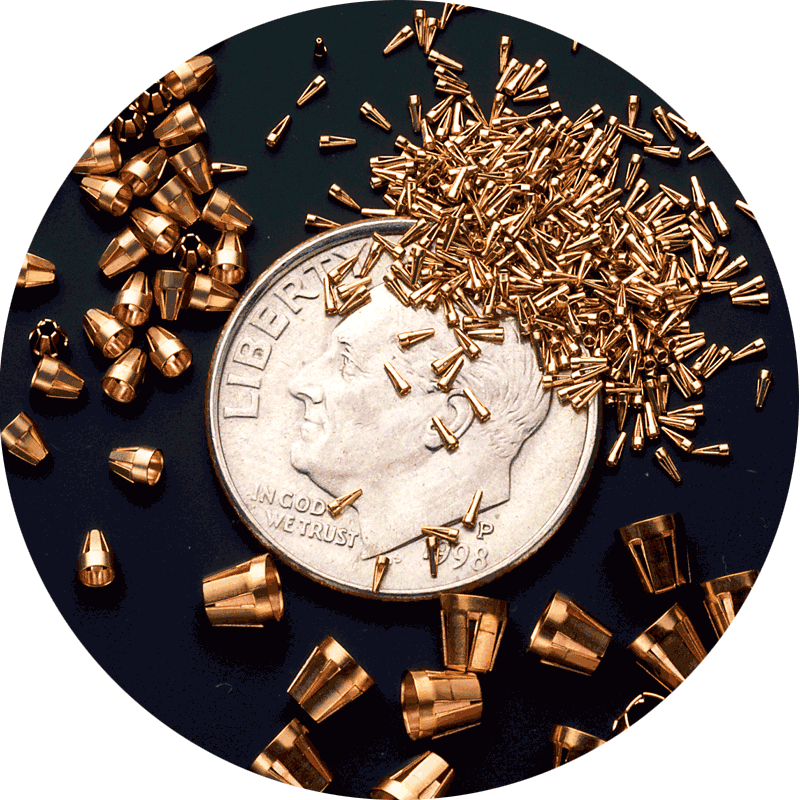

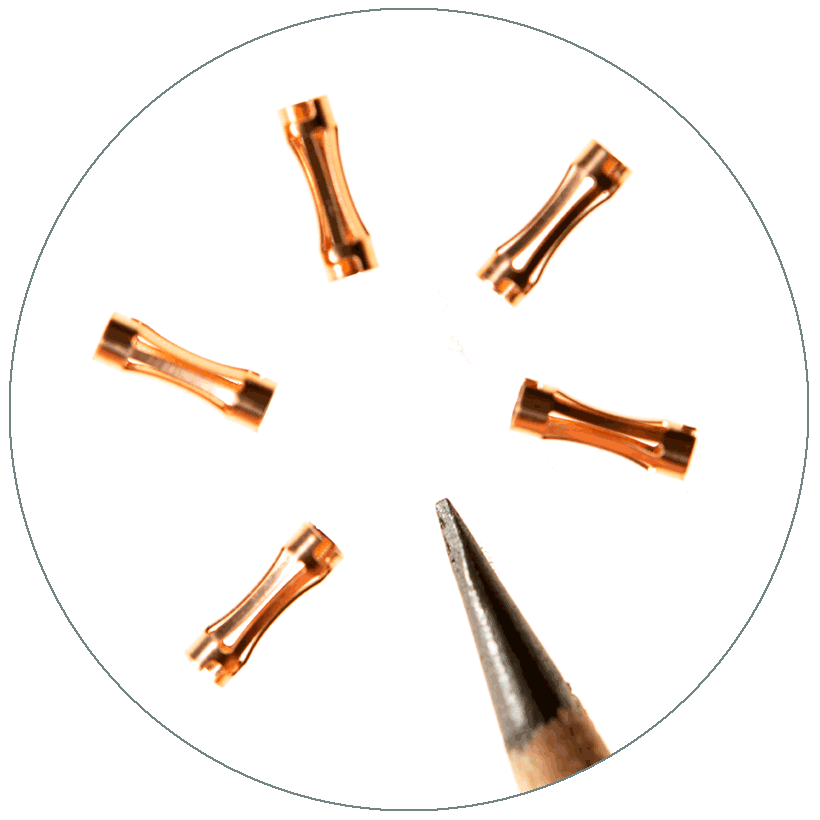

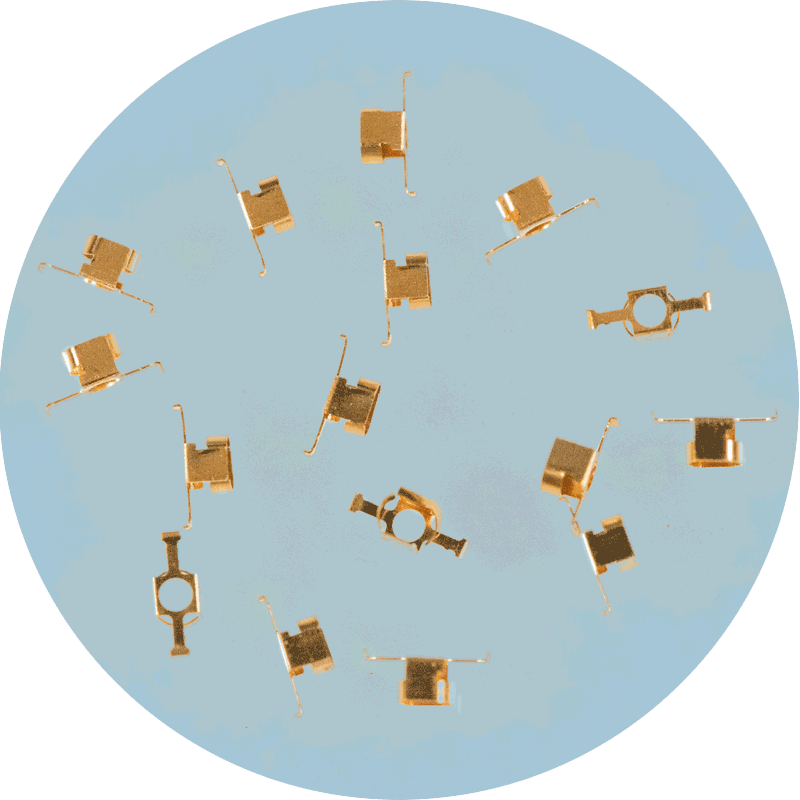

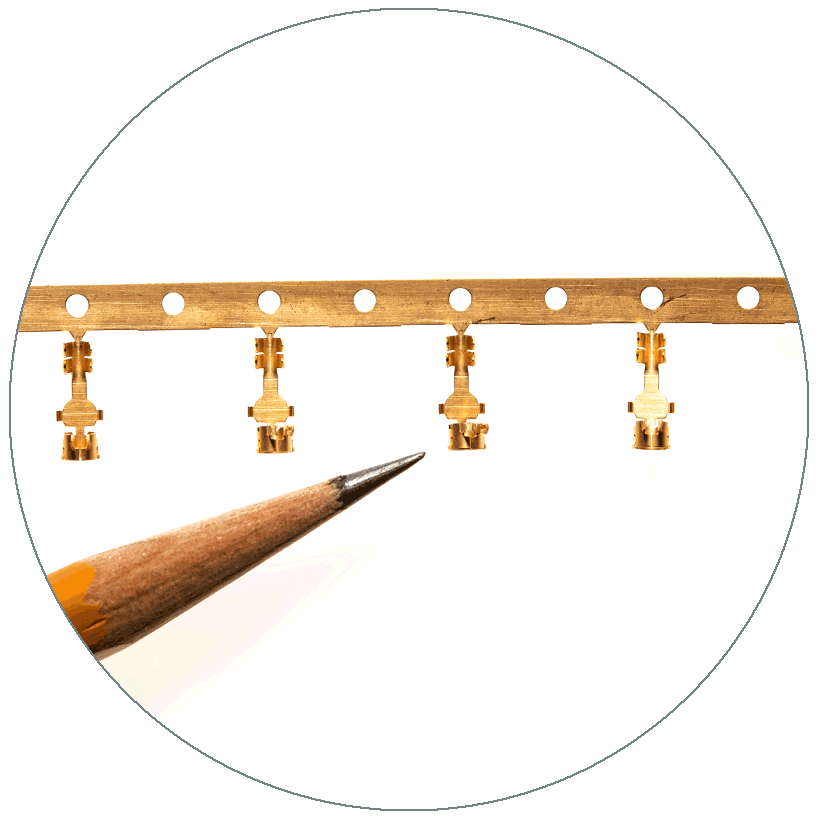

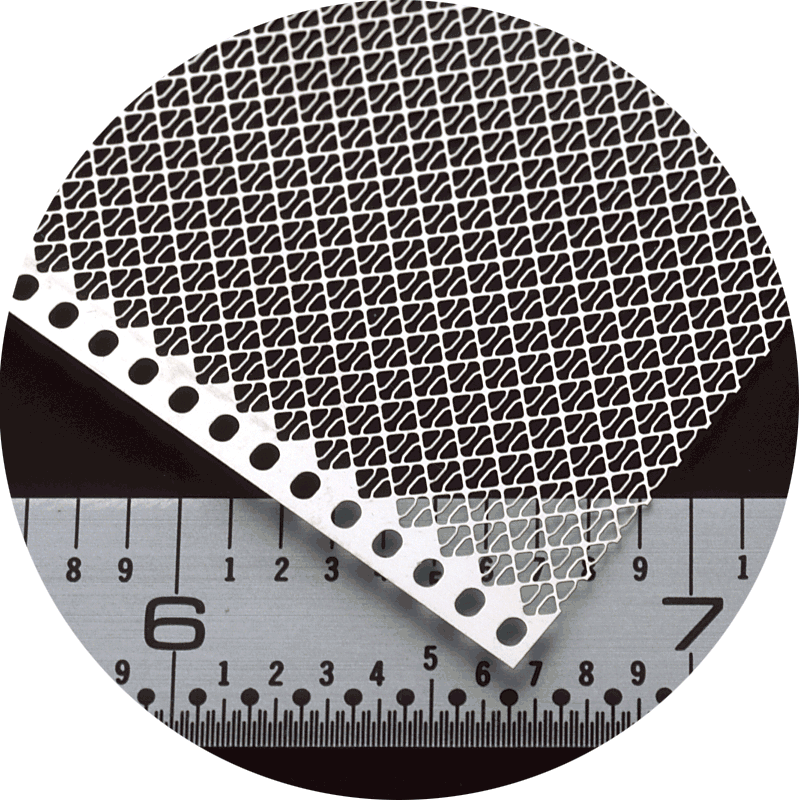

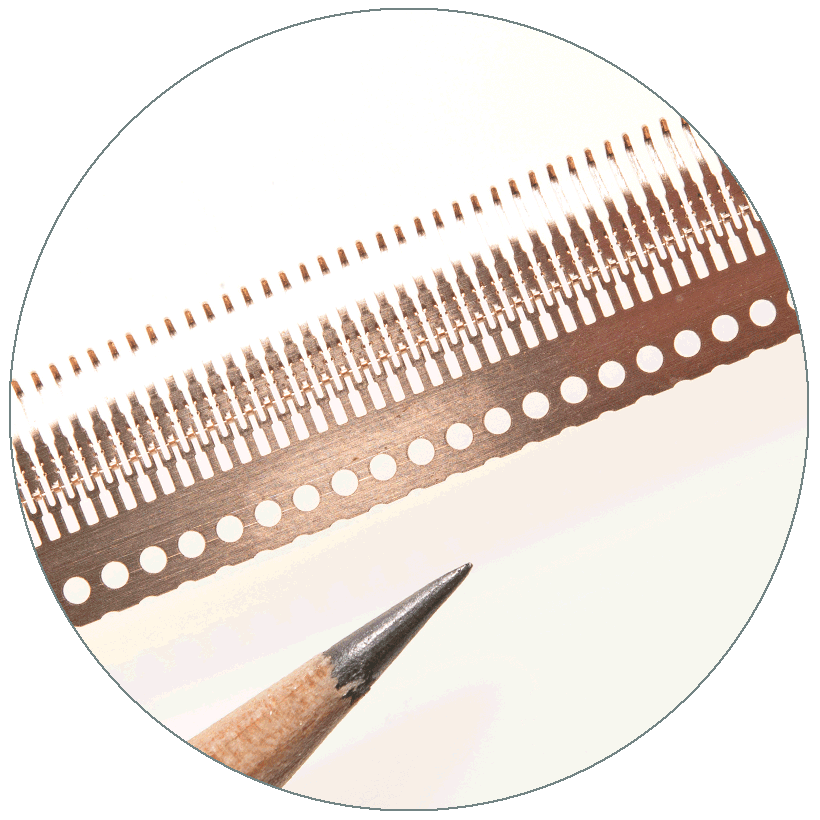

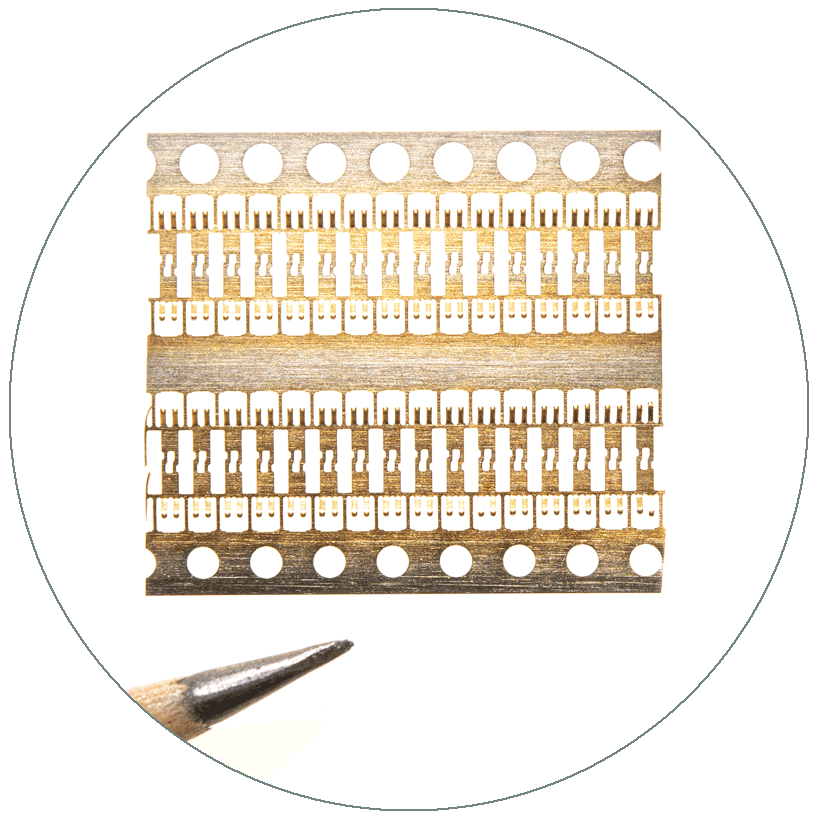

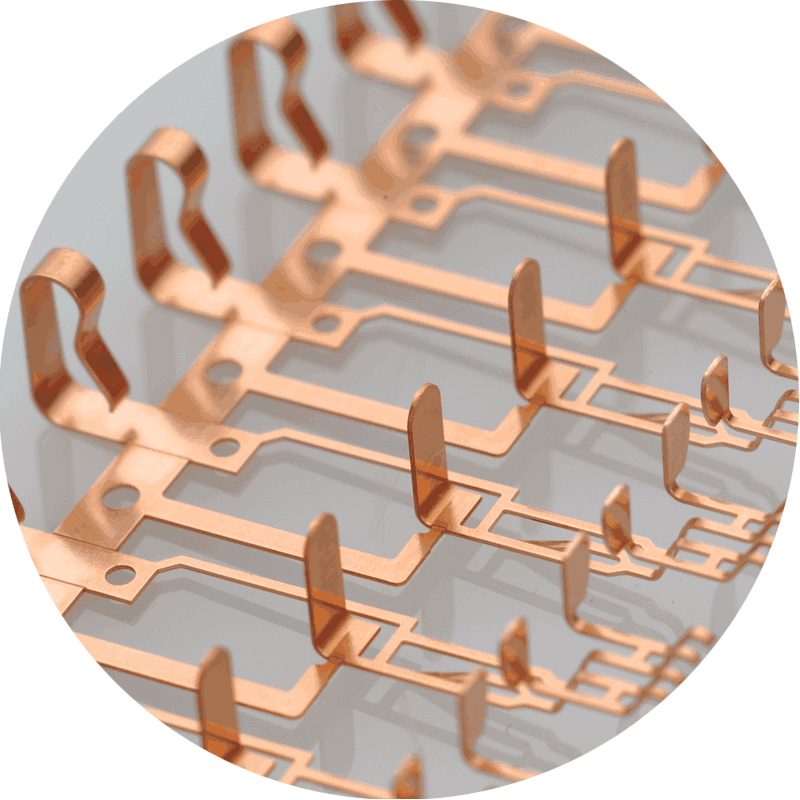

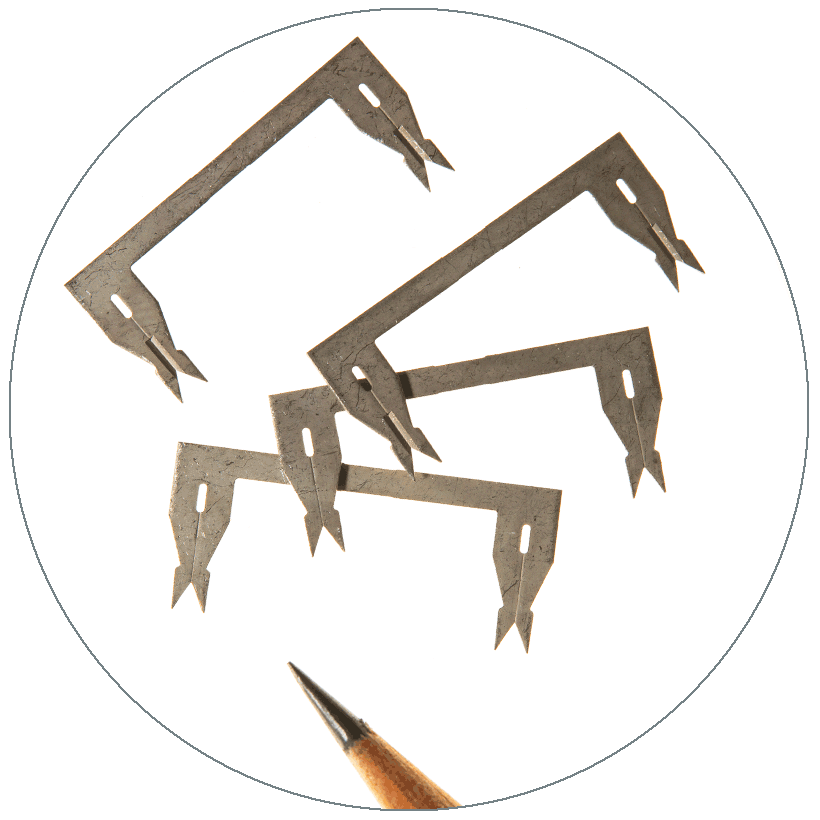

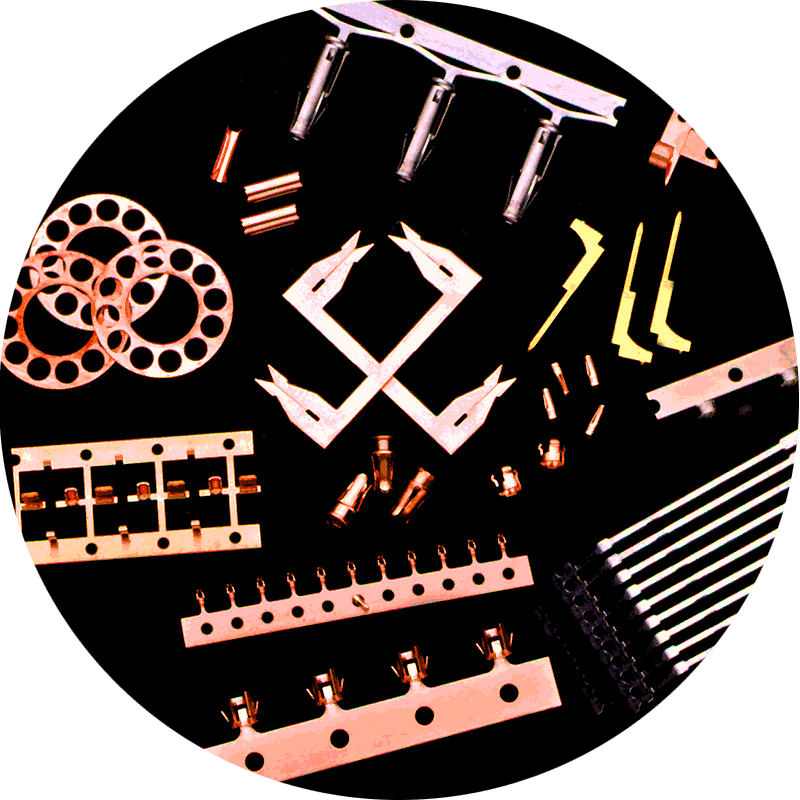

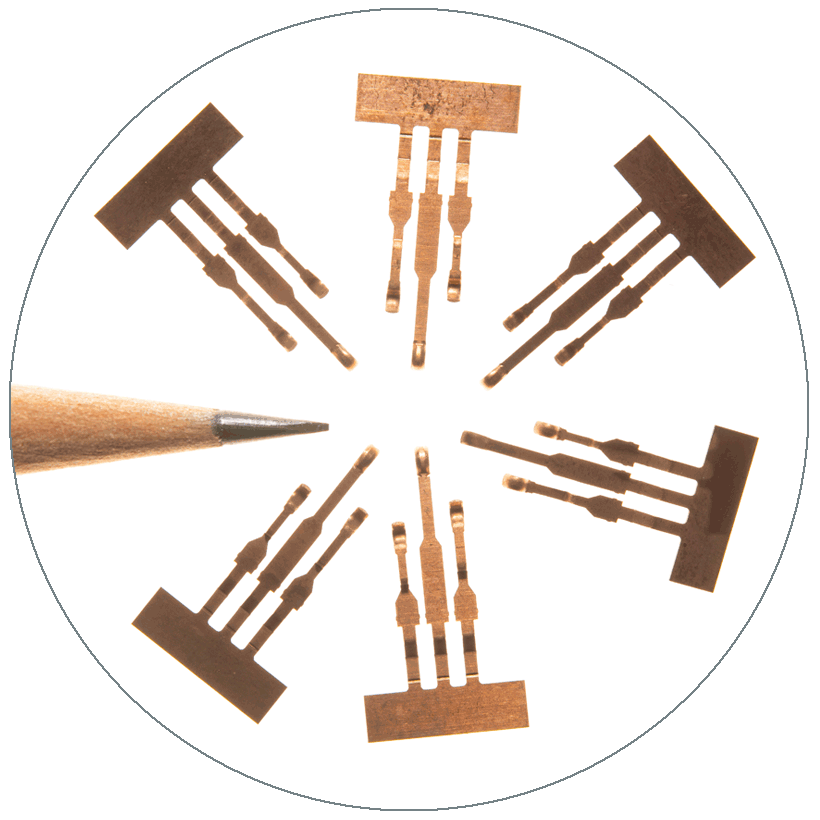

Quality Control for Small Stamped Metal Parts

Quality Control integration, start to finish.

Quality Control is a critical element for successfully and consistently stamping Small, Micro-Precision, and Micro-Miniature Parts. So at Ditron, we integrate documented Quality Assurance actions into every phase of our operation.

Our Strictly monitored Quality Control requires start-to-finish inspection integration that begins with initial discovery sessions. We define customers specification benchmarks, and then draft a quality ensuring road map that defines the “procedural inspections and reporting” necessary so specifications are met every time, at every phase, for every piece.

Quality Control for stamped parts that is pro-active.

Ditron’s Quality Control program continually tracks and compares customer specifications and real-time production dimensions using inspection tools like Nikon Optical Comparators. When needed, we implement Statistical Process Control (SPC), charting Cp/Cpk, ¯X and ¯R to ensure critical part dimensions and attribute characteristics are maintained during the production process.

Analysis of Quality Control data also enables us to identify or predict trends that could lead to future dimensional deviations. As a result, we can implement pro-active measures, changing or correcting process parameters before a defect occurs.

This “true partner” approach saves our clients material, stamping time, and helps to ensure on-time inventory delivery according to contract.

Small Stamped Part Quality Control with traceability and reporting.

For customers beginning a new tooling program, we provide a GANTT Chart—outlining all of the necessary tooling activities so that the customer can stay abreast of our program. During the F.A.I Sequence, process flow diagrams and inspection procedures are developed by the Quality Assurance team. This information is shared with the Ditron Inspection Department so all inspectors can be trained relative to the new product specifics.

Ditron traceability begins at the receiving dock, where raw material is inspected to ensure it meets stringent standards. Once approved, materials are assigned permanent identification numbers maintained throughout all manufacturing phases, right through shipping. We provide shipping lists, order tracking and fax confirmation for daily shipments leaving our facility.

As part of our “through date code” traceability process, we inventory inspection documentation along with product samples for a period of 10 years.

Ongoing Quality Control Improvement.

Ditron continuously strives to improve our process and small stamped part quality. We have been rated a Six-Sigma supplier (to IBM) since 1989. We are ISO 9001-2015 registered.

Quality Control through uncompromising customer service.

At Ditron, we have proven Quality Control extends beyond our ability to “mechanically “deliver defect-free small, Micro-Precision, and Micro-Miniature stamped products.

Our Quality Control value also extends through our service approach.

We serve as a true extension of each customer, sharing and applying collaborative team efforts for peace of mind that expectations are always understood, met, and maintained.Rapid response to customers and prospects is our mandated behavior, with all inquiries receiving prompt, courteous, result-delivering attention. Our commitment is to always respond to queries concerning product or production — and requests for quotations — within 24-hours or less