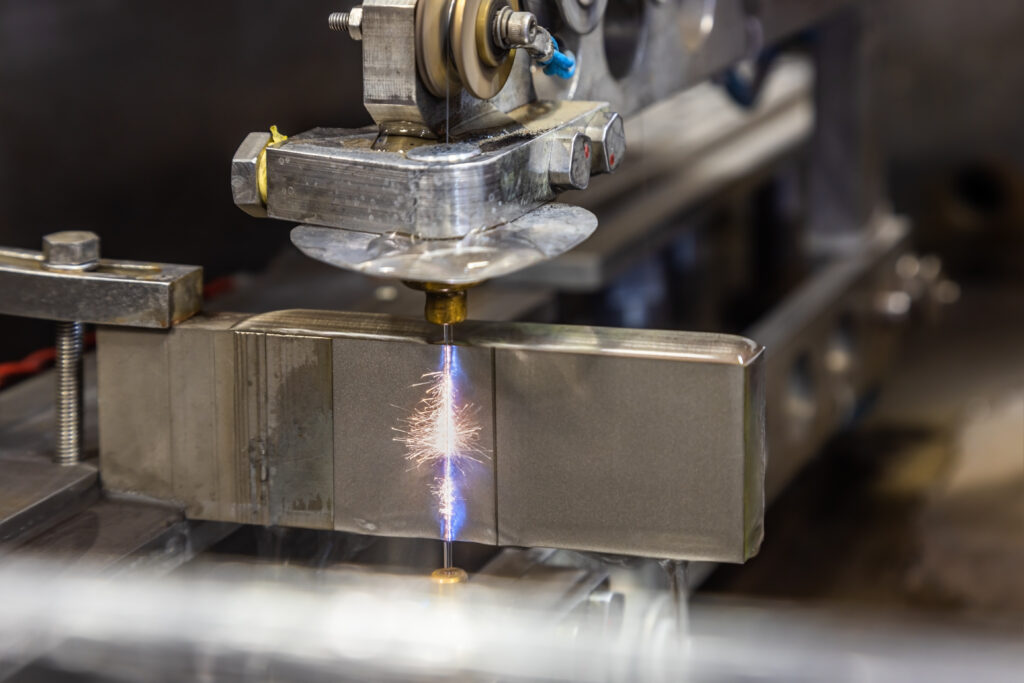

Cutting-Edge Wire EDM for Precision Tooling & Critical Components

Available Through the PrecisionX Group Platform: High-Precision Wire EDM Machining

As part of the PrecisionX Group platform, our Wire EDM (Electrical Discharge Machining) services deliver ultra-precise, high-quality solutions for tool and die making and the production of critical metal components. This advanced non-contact machining process allows us to cut complex geometries and fine features with exceptional accuracy—ideal for applications requiring tight tolerances and superior surface finishes.

We specialize in machining a wide range of electrically conductive materials, including:

Alumel, Chromel, Kovar

Inconel, Titanium, Stainless Steel

Copper, Nickel, Cold Rolled Steel (CRS)

Other hard-to-machine alloys

Our Wire EDM capabilities are engineered to meet the demanding standards of industries such as aerospace, medical devices, defense, electronics, and semiconductor manufacturing. Whether creating custom tooling or intricate production components, we ensure every part meets strict requirements for performance, durability, and precision.

Manufacture parts as large as 12 x 12 x 8”

Produce parts with inside corner radii as sharp as .003”

No limitation on outside corner radii sharpness

Any electrically conductive materials, including Alumel, Chromel, Kovar, Inconel, Titanium, Stainless Steel, CRS, Copper, and Nickel.

Create complex features with Wire EDM to achieve precise, intricate geometries and tight tolerances. Ideal for tool and die making or critical metal components, Wire EDM delivers sharp corners, fine details, and complex shapes with high accuracy on diverse materials, meeting even the most challenging design requirements.

Industries Served

Your partner in excellence.

Sitemap | Privacy Policy | Cookie Policy | Terms of Service | Copyright © 2025. | All Rights Reserved